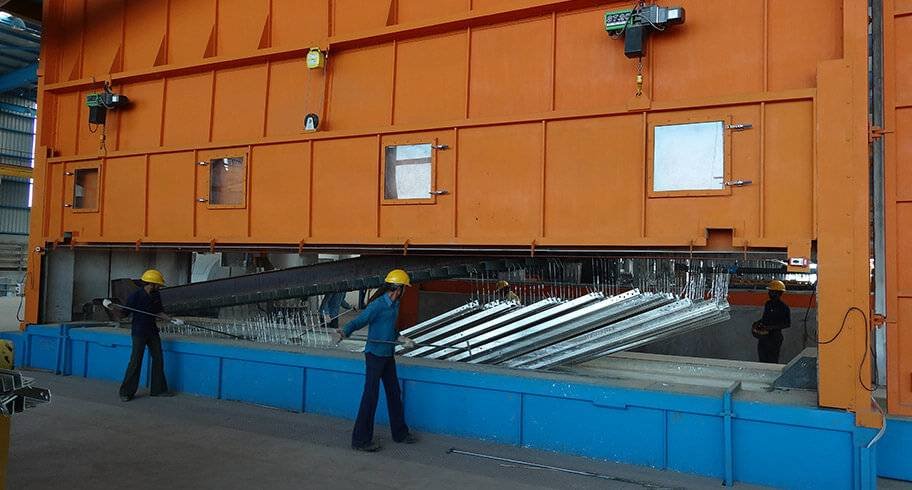

Quench and Passivation tanks are post-treatment tanks that are used to treat the workpiece after galvanizing it in the kettle. They are a significant part of the galvanizing process that completes the process of galvanization. Corrotech supplies top-notch quality quenching and passivation tanks made of mild steel and coated with epoxy paint that precisely meets your post-treatment requirements.

Quench tank is used to do the quenching process by rapidly cooling the material galvanized in the kettle to get the material properties. It prevents phase transformation of the material. Passivation tank is used to treat the material to reduce its chemical reactivity. It is used to make the galvanized material more rust-resistant.

Quench and passivation tanks end the galvanizing process and hold high importance. Source post-treatment tanks from a leading manufacturer like Corrotech and give a long-lasting life to the galvanized zinc and ensure great customer satisfaction. We customize premium-grade post-treatment tanks that would perfectly suit your complete plant facility.

Equipment Design

- Manufactured from high quality carbon steel

- Designed using latest software

- Manufactured in a wide variety of sizes and intended for intensive use

- Connection port for cooling tower

- Integration of flux heating system if needed

- Capable to take high liquid temperature

Benefits and Cost Savings

- High product quality

- Less rework and rejection in galvanized product

- Product highly aesthetic

Other Products

Explore our premium range of products that are specially fabricated for your galvanizing facility.