Galvanization is everywhere. It’s all around us. In fact, it wouldn’t be an exaggeration to the fact that we are surrounded by a plethora of things made of galvanized iron and steel. Since we are talking about galvanization, it makes sense to bring into focus the significance of the galvanization plant. How the scientifically designed unit is changing the socio-economic scenario around us? In this blog, we are highlighting turnkey hot dip galvanizing plants and their impact on changing the fortune of the automobile spare parts industry.

History of galvanized steel and automobile industry

According to industry experts, it wasn’t until the late 1980s, that the Japanese began focusing on automobiles that uses galvanized steel in their design. It makes sense to share that galvanized steel was indispensable in Japan, considering its geographical location. It is a country with a substantial coastal environment that creates heavier levels of oxidation and corrosion. Therefore, galvanization was necessitated.

Let’s now shift our focus to the core subject of this blog, how hot dip galvanization is changing the fortune of the automobile industry.

Galvanized steel parts are protective in nature

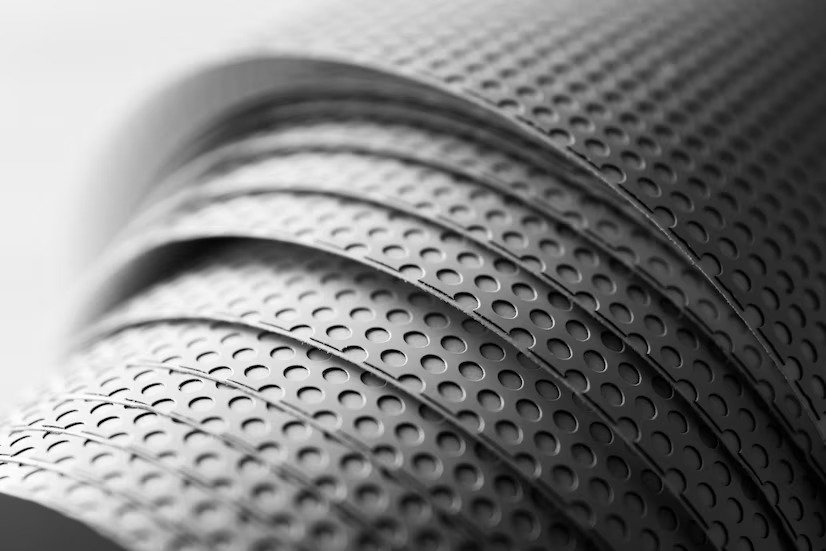

It is a proven fact that the galvanized steel part that is being used in cars, bikes, trucks, etc. lends protective cover to the vehicle. Sharp corners and edges are prone to oxidation. Galvanized parts used here protect the vehicle from corrosion.

Galvanized steel can be used immediately

Steel plates, frames, rooftops, etc. galvanized by using the hot dip galvanizing plant can be used immediately, unlike painted material. On the contrary, painting requires preparation of the surface, an inspection of the surface, painting/ coating, etc. It’s a time-consuming process. If you are an auto spare parts manufacturer, you can connect with a leading galvanizing plant manufacturer in Ahmedabad.

Increased durability

This is again an important factor of galvanized steel that drives the automobile industry to move towards galvanized steel. Increased durability means reliability. At the same time, it decreases the maintenance cost or saves your hard-earned money in maintaining your favorite car. You don’t have to drag your car for repairs and maintenance. That’s why even buyers, the end user prefers car manufactured using galvanized steel parts.

Self-healing property of galvanized steel

Oxidized parts corrode rapidly leading to the collapse of the vehicle. Whereas galvanized steel has this unique feature of self-healing. What does that mean? It means the galvanized steel provides automatic protection for damaged areas. The zinc coating will corrode especially the steel. As a result, sacrificial protection is provided to the damaged areas.

Over the years, the use of zinc-coated spare parts and bodies in auto manufacturing has gained momentum. At the same time, the anti-corrosion feature is also a brilliant marketing tool for the automobile industry. Galvanization empowers automakers to attract customers by offering anti-rust warranties.

Conclusion

Considering the benefits of galvanizing plants for the automobile industry, many automobile spare parts manufacturers are moving towards galvanized steel. And rightly so.