In this industry-centric blog, our focus will be hot air circulation dryer, its features, and how it impacts the galvanizing industry.

Before we take a deep dive into the crucial manufacturing industry-related subject, it makes sense to learn about the product in plain language. It will help the readers in connecting with the content better and expand their knowledge about hot air dryer.

Learning about the hot air dryer

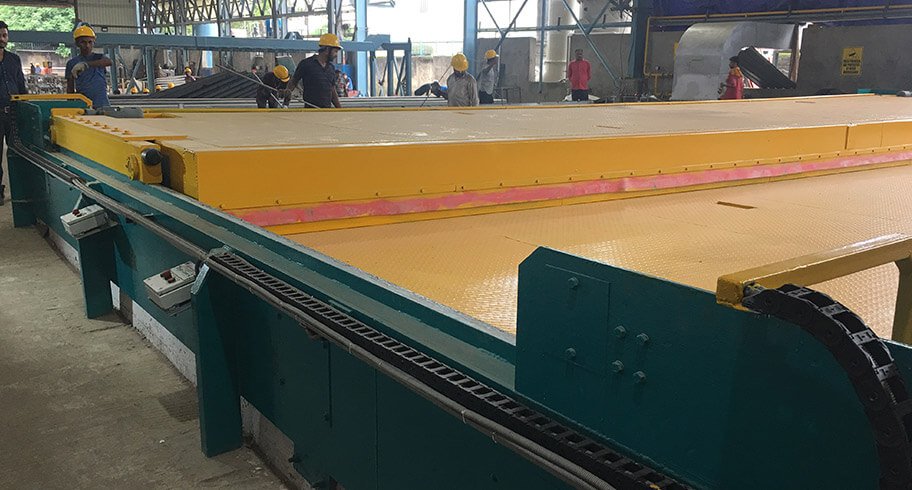

The quality-driven and precision engineered machine is integrated with the galvanizing furnace. It is designed and manufactured to pre-heat the structural steel by re-circulating the exhaust flue gases that generate from the furnace. The hot air is utilized for complete drying and preheating of the steel/ metal to be hot dipped in the molten zinc. It facilitates a faster reaction. Consequently, this leads to reduced fuel consumption. Additionally, controls the loss of zinc due to spurting. Sounds amazing, that’s how the machine impacts the hot dip galvanization mechanism.

Salient features of a quality-driven hot air circulation dryer

From the basics, let’s now shift toward the salient features of the product. Why? As an owner of a company that is using the galvanizing plant for the galvanization of products, it’s vital to install and commission-only a quality-driven product. The reason is – that only a quality-driven product with drying chamber has the competency to meet your business goals. The ensuing content talks about salient features of the product:

- Energy efficiency

- Sturdy design

- Proper temperature rated components,

- Proper sizing of air recirculation (to get a reasonable air velocity and number of air changes per minute) and burner components,

- Powerful exhaust system and air flow

- Oven workmanship

- Detailed operation and maintenance manual

- Easy to install and commission

- Easy to maintain and clean

- Optimized and uniform heat distribution

- Durable

Important design qualities of the machine

While buying the machine, don’t forget to raise important design features to the manufacturer and supplier, including:

- Heat recovery system that eliminates the requirement of auxiliary burners.

- PLC based automatic temperature control system

- Uniformity of temperature

- Uniformity of airflow

Benefits of hot air circulation dryer for industries

Now it’s time to bring focus on another important issue, the benefits of hot air circulation dryer. Here are the advantages of the product for our readers. It will further expand the knowledge of readers and at the same time advocate the use of the machine in the galvanizing setup.

- Lower zinc consumption

- Minimizes fuel consumption

- Competent to eliminate zinc splash

- High product quality

- A clean environment in the workplace

- Creates a safe working environment for workers

- Energy conservation

The hot air dryer machine operates within an open cycle. The ambient air is fetched through a filter, allowed to heat, and then passed through the resin granulate in the drying hopper. Afterward, the hot air vented to the factory floor.

For detailed information, you can get in touch with Arvind Corrotech, a leading hot air dryer manufacturer in Ahmedabad.

Control of drying temperature

How to control the drying temperature? This is an important feature of the quality-driven hot air dryer. A quality-driven machine is competent to control drying temperature and airflow by the blower unit.Heat transfer

How does the hot air dryer transfer heat? The machine is designed to transfer heat through the convection mode.

Last but not the least, the current relative humidity of the ambient air is a key factor as it impacts the outcome of the machine.