Tag: acid storage tanks

Doesn’t matter whether you run a big industry or a small one, acid storage tanks are crucial in every field including pharmaceuticals, waste treatment, and chemical manufacturing. These tanks are crucial as it stores hard and harsh substances which cannot be left in open as it can cause serious harm. While finalizing an acid storage tank, it is important to look for its major features. This is because every acid storage tank comes with some specific safety measures, durability, and operational standards. Therefore, it is important for business owners to check the major features of acid storage tanks before finalizing one. So, let’s discuss in detail and find the best tank for your use.

Material Composition

In business, acid tanks are majorly used for storing important chemicals and acids. Here, the most critical aspect of acid storage tanks is their material composition. These tanks are typically made from special material that can withstand the acid’s corrosive nature. So, here it is important to find the finest material. Go for stainless steel if you want a material that is high resistance to corrosion, as it can handle a variety of acids. Go for polyethylene for certainly less aggressive acids, as a high-density polyethylene offers excellent resistance to corrosion, is very lightweight, and it is suitable for all types. Last but not the least , go for fiberglass reinforced plastic (FRP) as it is corrosion resistant and full of strength, which makes it ideal for many chemical applications.

Ventilation Systems

When it comes to storing anything, ventilation plays a crucial role. This is the same in the case of acid storage tanks as ventilation helps in preventing the buildup of hazardous gasses. There are acids that can release unwanted vapors that pose serious health risks along with pressure buildup within the tank. So, choose the right acid storage tank to control pressure and disperve vapors along with a well designed ventilation system.

Temperature Control

Temperature plays a significant role in affecting the stability of stored acids. A fluctuation in temperature control can lead to vapor formations, pressure changes, and even major chemical reactions. Therefore, before going for any tanks it is important to check its insulations and cooling & heating systems. Insulation is important if you want to maintain a stable internal temperature. Along with this, it is important to manage temperature extremes, which will ensure that the acid does not degrade and it also remains stable.

Regulatory Compliance

As a business owner, you cannot just buy a tank and install it. Acid storage tanks is used in various national, local, and international regulations. Before buying a tank, make sure to check all the compliance so that it can be checked that your tank meets all the environmental, safety, and operational standards. Some major key regulations includes EPA regulations and OSHA standards. In EPA regulations, the environmental protection agency governs the impact of chemical storage on chemicals. On the other hand, OSHA (Occupational Safety and Health Administration) sets and look after the working standards of workplace safety. Regular auditing and updating is crucial here to avoid legal repercussions and actions.

Accessibility for Maintenance and Inspection

Regular inspection and maintenance is important if you want your tanks to work safely, for a longer period of time. Moreover, when it comes to acid storage tanks, it is important to design it with accessibility in mind which allows a range of operations. Always conduct visual inspections to check corrosion, leaks, and wear. In addition, always facilitate repair work and cleaning with a well planned routine. This will ensure that tanks are accessible easily and can help prevent small issues from big issues, which will ultimately enhance efficiency and safety.

Corrosion Resistance

The primary feature of acid storage tanks is its corrosion resistance feature. The tanks functionality is highly affected by its storage environment therefore, it is important that the tanks must be constructed and treated with materials that prevent any kind of chemical reaction with the stored acids. In addition, to keep the tanks working smoothly, it is important to conduct regular inspections. This will ensure that there are no signs of corrosion along with its functionality and safety.

Robust Design and Construction

One cannot overlook or take lightly the structural integrity of acid storage tanks. This is because these tanks store harsh chemicals and are exposed to harsh environmental conditions. The design of your acid storage tanks must be accountable for wide loads and seismic considerations. Wide loads if the tanks are used in high winds or strom areas, and seismic considerations to withstand natural calamities like earthquakes, etc. A robust construction design ensures that the tank is safe enough to contain acids under a range of conditions, reducing the risk of accidents.

It is clear that acid storage tanks are super complex structures that are designed to contain harsh and hazardous material with safety. But handling it is not a hard task if all the features of the tanks are kept in mind, protecting both the environment and their workers. So, to enhance the overall production of the business and to handle the harsh chemical easily, invest in high-quality acid storage tanks. Contact Arvind Corrotech if you are willing to invest in acid storage tanks.

This blog is informative, particularly for those who work in industrial units that use acid storage tanks and chemical storage tanks for various purposes. In this blog, we are going to highlight acid storage tanks, their benefits, and their advantages for different types of industries.

Learning about industrial acid tanks

Large and bulky-sized tanks that are designed and manufactured to store and process different types of chemicals for industrial applications are called industrial storage tanks.

Let’s now shift our focus to the unique features of industrial chemical storage tanks. How will you identify the quality of the industrial tanks? In the ensuing sections, you will learn about the salient features of quality-driven storage tanks.

Salient features of quality-driven acid storage tanks

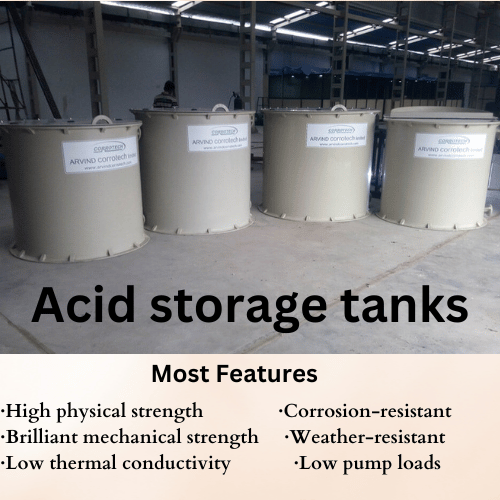

Here are the salient features of quality-driven industrial tanks:

- It is adaptable to a wide range of temperature

- High physical strength

- Brilliant mechanical strength

- Low thermal conductivity

- Excellent insulating material

- Corrosion-resistant

- Weather-resistant

- Low pump loads

- Easy to handle

- No maintenance

- Durable & having a long service life

- Economical & cost-effective

Before considering these features, you should buy industrial tanks for your manufacturing unit.

Material of acid Storage tank

Others manufacture industrial tanks using premium-quality polypropylene sheets, HDPE, and FRP. Every material has its unique features and benefits.

Which material is suitable?

You can connect with a leading chemical storage tank manufacturer to learn more about the storage tanks. The material of the tank varies from chemical to chemical.

Benefits and advantages of acid storage tanks

Industrial requirements necessitate the design of bulk–sized tanks for bulk storage of chemicals and acids; these tanks are cost–effective in the long run, as bulk buying chemicals is cheaper compared to retail, while also reducing the number and cost of deliveries. Furthermore, chemical storage is used in a variety of operations when necessary, making industrial acid storage tanks ideal for storing, processing, and safely transporting chemicals.

Industries using acid storage tanks

Numerous industries are drawing benefits from chemical storage tanks, PP storage tanks, HDPE storage tanks, etc. These include Pharmaceuticals, Chemicals, Petroleum, Steel, Textile, Plastic, and a host of others. For more information, you can connect with a leading chemical storage tank manufacturer in Ahmedabad, India.

Process tank

The engineer designs industrial tanks to blend, separate, cool, and purify a wide range of processes and sub-processes. While placing your order, you can discuss the need and requirements of your industry with the chemical storage tank manufacturer.

Conclusion

Acid storage tanks are integral to a wide range of manufacturing industries. Quality makes the difference in this era of tough competition. Many industrial tank manufacturers have flooded the market. Only buy the product from an established chemical storage tank manufacturer.

Over the years, the galvanizing industry has grown manifold, riding on ever-increasing demand for galvanized products across the globe, including in our very own India. Galvanizing plant setup is highly sophisticated engineering, only a few turnkey hot dip galvanizing plant manufacturer and supplier hold expertise in the domain. Effective consulting with a prominent manufacturer will go a long way in this regard. This brief guide will help you meet your industrial requirement.

Why should you consider galvanizing plants?

In this section, we are going to highlight a few important factors that favour a galvanizing plant setup, if you are considering entry into the galvanization business. These include:

- Short production times

- Streamlined process

- Reduced cost

- Affordable costing

- Reduced labour costing

- Cost savings

- Growing demand for galvanized products

- The durability of galvanized products

Apart from these features, we recommend you to meet a leading company in this area. Their engineers will help you learn the essentials related to the important plant.

Purchasing an existing plant

Experts into galvanizing businesses suggest taking over an existing galvanizing plant as it’s more advantageous to purchase an existing business in comparison to starting from scratch.

Existing revenue cycle

When you build a plant from scratch, you have to struggle to bring in revenue right from the word go. On the contrary, an existing plant has a steady income as it has a client base in its funnel.

Operational efficiency

This is again a huge advantage of galvanizing plant set by leading galvanizing plant manufacturers. As an owner of a business, you don’t have to worry about the operational efficiency of the plant, since the plant is already pilot tested by the manufacturer.

Are you planning to enter into a galvanizing business?

Entering into a dialogue with a few entrepreneurs who are managing a galvanizing plant setup will considerably help you to understand the galvanizing business and how it is going to help your business.

Here we would like to recommend you connect with entrepreneurs from other cities. Why so? It’s unlikely that the local competitors would be eager to speak with you. Obviously, why would they like to guide and educate a future competitor? Whereas galvanizing plant setup owners from far away cities will have no objection as they are fully aware that since you are from a different city, you are not going to steal their local customers. Sounds interesting! It’s a bitter truth.

The bitter truth is it can take a while to find an entrepreneur from the crowded market who will be excited to discuss with you the business of galvanization, market demand, the future of turnkey hot dip galvanization plants, etc.

Important features of a galvanizing plant setup

Before you buy or acquire a galvanizing set up in Ahmedabad, India, examine the plant on major quality parameters.

- Excellent design

- Quality of the machinery

- Cost-effectiveness

- Robust setup

- Impeccable commissioning

- Technology used

- Power efficiency

- Durability

It’s important to carry out due diligence exercise, then regret it later.

A few leading engineering companies in galvanization also hold professional expertise to deliver and supply acid storage tanks. Such manufacturers are known as acid storage tank manufacturers.

In this blog, we are going to highlight about an important industrial product, acid storage tanks, the benefit of the product, and its applications among others.

At the outset, let’s understand the product in simple language.

What is an acid tank?

These are specially designed tanks to store industrial acids and chemicals. Engineered keeping in view the physical and chemical properties of the acid, the industrial tanks are apt for the safe storage of acid.

The material used to manufacture the tanks

Given the properties of acids,Acid storage tanks manufacturers are manufacturing the storage tanks by using the following materials:

- Stainless steel tanks

- Polyethylene tanks

- Fiberglass (FRP) tanks

Important features of the industrial acid storage tanks

The industrial storage tanks are designed to store a wide range of chemicals. These are identified with numerous salient features. Here are the major features of the industrial tanks:

- It is adaptable to a wide range of temperature

- High physical strength

- Weather-resistant

- Low pump loads

- Easy to handle

- Brilliant mechanical strength

- Low thermal conductivity

- Excellent insulating material

- Corrosion-resistant

- No maintenance

- Durable & having a long service life

- Economical & cost-effective

These industry-specific tanks are engineered to store several types of manufacturing industry-centric chemicals. Your manufacturing industry requires a quality-driven product. When purchasing the product, make sure it meets the above quality features.

For in-depth knowledge, you can connect with reputed acid storage tank manufacturers. Never settle for less. Industrial acids and chemicals are different from traditional fluids. As a result, special purpose tanks are required.

The objective of Industrial storage acids tanks

The industrial tanks are designed and manufactured for the safe storage of a wide range of chemicals and acids. At the same time, the tank is suitable for the transportation of acids from one location to another.

Furthermore, the tank is suitable to provide the required pressure to the distribution system. Therefore, a tank can serve one or multiple objectives, depending basically on the industrial requirement. Configuration, shape, size, etc. varies from company to company.

Industrial acids

Let’s now talk about industrial acids in brief. Some of the widely used industrial acids are sulfuric acid, hydrochloric acid, nitric acid, lactic acid, and acetic acid. These acids are used in different types of industries. For detailed information, you can speak with a few reputed acid storage tank manufacturers in Ahmedabad, India.

Industries drawing benefits and advantages from the acid tank

Plenty of industries are benefitting from the industrial product. These include chemicals, Pharmaceuticals, Petrochemicals, Desalination, Power, Refinery, Sewage treatment plants, and a host of others.

Dimensions

The industrial acid storage tanks are available in different types of dimensions, shapes, and sizes, like vertical and horizontal. Based on your industrial requirements, you can choose the dimension. A few acid storage tank manufacturers in Ahmedabad are professionally competent to deliver custom-made solutions for your industry. In case you are seeking a custom-made solution for your industry, don’t think twice to take benefit of this specialized service.

Conclusion

As the name indicates, the acid tank is designed for the storage of acids. The quality of the tanks plays a huge role in durability and maintenance. Subsequently, we recommend that buy products from reputed acid storage tank manufacturers.