Tag: Chemical storage tanks

Over the years, industrial HDPE Chemical Storage Tanks have assumed significance considering their benefits for a variety of industries. Industrial chemical storage tanks are specially designed to store industrial chemicals, acids, solvents, etc. Choosing a suitable tank is always a challenge for industry owners and decision-makers.

You would be surprised to learn that many companies realize after buying the product that the tank they have just bought doesn’t meet their industrial requirements.

How to choose the best quality tank for your industry? This blog will serve as a guide in this regard. Whether you’ve been buying the HDPE tank or any other industrial tank for years, or shopping the tank as a beginner, this guide is definitely for you.

A brief guide to choosing the premium quality HDPE chemical storage tank

Consider the chemical to be stored

To begin with, the first step you can take to choose the best HDPE tank is to consider the chemical to be stored. At the same time, carefully consider the properties of the chemicals to be stored inside the tank.

Types of chemical storage tank material

When you are sure about the chemical to be stored and its unique physical and chemical properties, you can then move towards the best tank material suitable to meet your industrial requirements.

Industrial tanks are made up of a variety of materials, including HDPE, PVC, Steel, FRP, PVDF, Plastic, etc. Before choosing the material, have a long discussion with a few leading industrial tank manufacturers in Ahmedabad, India.

Size

This is again an important step to be considered when choosing the tank. Here size means the capacity of the tank. What type of chemicals do you want to store for your industry? Consider the capacity of the tank.

If you are planning to buy an HDPE tank to store industrial chemicals for your company, discuss the capacity with the premium quality HDPE chemical storage tank manufacturers and suppliers.

Durability

The next step, you can consider when choosing an industrial tank, like an HDPE tank is – the durability of the tank. Every material has definite durability. How much that industrial tank will last matters for your business. Short life means you have to invest in storage tanks every now and then.

When you buy long-lasting industrial tanks, you are ensuring the quality as well as durability of the tank. Higher durability also means you don’t have to invest time and again in storage tanks.

Why quality matters

Harsh chemicals gradually wick into the walls of the chemical storage tanks over time. The chemical spreads into the structural area of the tank. The structure begins to break down and eventually the tank collapses.

If quality isn’t up to the mark, it will impact the overall life of the storage tank. Therefore, it makes sense to buy the premium-quality chemical storage tanks

Conclusion

This guide on choosing the premium quality HDPE chemical storage tank will definitely benefit you, helping you to get the best product for your manufacturing unit. Important aspects like tank design, shape, size, capacity, etc. should never be undermined when choosing an HDPE tank.

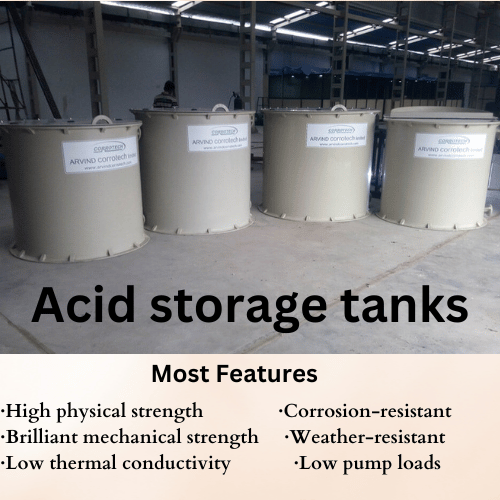

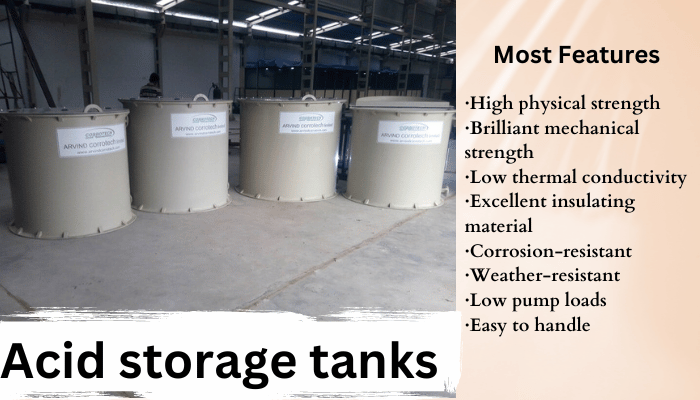

This blog is informative, particularly for those who work in industrial units that use acid storage tanks and chemical storage tanks for various purposes. In this blog, we are going to highlight acid storage tanks, their benefits, and their advantages for different types of industries.

Learning about industrial acid tanks

Large and bulky-sized tanks that are designed and manufactured to store and process different types of chemicals for industrial applications are called industrial storage tanks.

Let’s now shift our focus to the unique features of industrial chemical storage tanks. How will you identify the quality of the industrial tanks? In the ensuing sections, you will learn about the salient features of quality-driven storage tanks.

Salient features of quality-driven acid storage tanks

Here are the salient features of quality-driven industrial tanks:

- It is adaptable to a wide range of temperature

- High physical strength

- Brilliant mechanical strength

- Low thermal conductivity

- Excellent insulating material

- Corrosion-resistant

- Weather-resistant

- Low pump loads

- Easy to handle

- No maintenance

- Durable & having a long service life

- Economical & cost-effective

Before considering these features, you should buy industrial tanks for your manufacturing unit.

Material of acid Storage tank

Others manufacture industrial tanks using premium-quality polypropylene sheets, HDPE, and FRP. Every material has its unique features and benefits.

Which material is suitable?

You can connect with a leading chemical storage tank manufacturer to learn more about the storage tanks. The material of the tank varies from chemical to chemical.

Benefits and advantages of acid storage tanks

Industrial requirements necessitate the design of bulk–sized tanks for bulk storage of chemicals and acids; these tanks are cost–effective in the long run, as bulk buying chemicals is cheaper compared to retail, while also reducing the number and cost of deliveries. Furthermore, chemical storage is used in a variety of operations when necessary, making industrial acid storage tanks ideal for storing, processing, and safely transporting chemicals.

Industries using acid storage tanks

Numerous industries are drawing benefits from chemical storage tanks, PP storage tanks, HDPE storage tanks, etc. These include Pharmaceuticals, Chemicals, Petroleum, Steel, Textile, Plastic, and a host of others. For more information, you can connect with a leading chemical storage tank manufacturer in Ahmedabad, India.

Process tank

The engineer designs industrial tanks to blend, separate, cool, and purify a wide range of processes and sub-processes. While placing your order, you can discuss the need and requirements of your industry with the chemical storage tank manufacturer.

Conclusion

Acid storage tanks are integral to a wide range of manufacturing industries. Quality makes the difference in this era of tough competition. Many industrial tank manufacturers have flooded the market. Only buy the product from an established chemical storage tank manufacturer.

This isn’t a conventional subject for our readers, yet, it has great significance for everyone. Directly or indirectly, chemical tanks are touching our lives. For those who are working or associated with the textile, chemical, petrochemical, food and beverage, and pharmaceutical industries, this is going to be an interesting subject. This will further expand their knowledge base about the subject. For students and research scholars, this is going to present a wide range of facts and figures enabling them to prepare their reports and assignments.

What is a chemical tank?

Before heading towards the intricacies of the subject, it’s important to learn the term in simple language. A chemical tank is a sophisticated storage container to store a wide array of chemicals that are in use in numerous industries, including pulp and paper. The sophisticated tanks are available in numerous sizes and standard shapes. Depending on chemical and fluid, chemical tank manufacturers across India fabricate these sophisticated tanks.

Why are we using the word sophisticated though it’s only a tank? The tank looks ordinary in design, a cylindrical structure, but this kind of tank is for special chemicals. These chemicals are hazardous in nature, may lead to disaster and environmental consequences, if not stored with adequate measures. While purchasing the tank for your manufacturing process, don’t forget to ask for features from the chemical tank manufacturer.

Purpose of chemical tanks

What is the purpose of a chemical tank? Is it only for storing? Calling the tank a storage tank delimits its benefits and industrial applications. It has numerous uses, including:

- Storage of industrial chemicals and fluids

- Chemical process

- Mixing of chemicals for a wide array of processes

- Transportation of finished products

- Transportation of raw material

A picture is crystal clear now. A chemical tank is a versatile container with numerous uses as mentioned above.

Types

Tanks are of different types. These are identified with the type of chemicals they hold.

- Acid tanks

- Holding tanks

- Feed tanks

- Blend and mix tanks

- Pressure vessels

- Buffer tanks

- Pump tanks

- Reactors

- Receiver tanks

- Filtrate tanks

- Stripper/Scrubber Columns

- Surge tanks

- Weighing vessels

- Jacketed tanks

- Solution tanks

- Solvent tanks

- Storage tanks

- Circulation tanks

Over the years, demand for chemical storage tanks has increased substantially. Storing chemicals is a challenging task. An ideal industrial chemical storage tank offers a financial and business advantage, as a businessman and a professional heading a company that’s what you require and expect from a chemical tank and chemical tank manufacturer.

Material and chemical

A chemical tank is designed to store a few selected chemicals only. Every tank has its specification and features. Since hazardous, industrial chemicals should be stored according to the standard instruction. You can take guidance from a chemical tank manufacturer.

- Hydrochloric acid

- Sodium hypochlorite

- Sodium hydroxide

- Ferric chloride

- Soda ash sodium carbonate

- Industrial wastewater

- Sulfuric acid

- Urea exhaust

- Petrochemical exhaust

Chemical storage tank manufacturers across India, including Ahmedabad, are constantly working towards using the latest technology and innovation to enhance the quality of the tank.

The current market scenario and impact of the corona pandemic

According to industry experts, the industry is heading towards a positive growth trajectory with increasing opportunities in the petrochemical, food, and beverages, and pulp and paper industries. The corona-induced pandemic havoc is affecting the growth of the market. The global chemical storage tank market will recover from the havoc in the current FY 2021 and it is poised for substantial growth, it is expected to reach an estimated $5.3 billion by 2025.

Buy from an expert only

As mentioned in the blog earlier, quality matters. Buy product from a leading chemical tank manufacturer only with a proven track record.

Manufacturing units and chemical companies use a wide range of tanks for various applications. Applications include surface treatment processes and storage tanks. Furthermore, these tanks are available in different types and configurations and play a significant role. These tanks store intermediate, semi-finished, and final products. Besides, the tanks are also used to complete many important processes.

In this short and important write-up, we are focusing on the role and application of tanks. Besides, industries using the product will remain our important priority.

Different types of tanks

The design, construction, and operation of tanks require experience and expertise. Besides, crucial subjects like chemical and acid compatibility with tank material, leaks, spills, loading, and unloading also present various challenges and environmental threats.

There are several types of tanks, depending on their applications.

- Chemical process tanks

- Storage tanks for industrial chemicals

Chemical process tanks

Tanks for chemical/ surface treatment processes require brilliant design and construction as the tank comes across numerous challenges. Moreover, such tanks undergo various tests and experiments to ensure their competency to withstand chemical and physical challenges. All worst-case scenarios are visualized, created, and experimented with to finalize the design and ensure quality.

Material

These tanks are completely different from normal tanks. In addition, special-purpose tanks use HDPE, & PP (non-metallic) among others to manufacture.

Why do industries use specific tanks?

Industrial tanks perform a wide range of applications and are suitable for use where MS tanks do not work. Arvind Corrotech is a leading company with a modern manufacturing facility in Ahmedabad, India. It offers a wide range of excellence-driven Chemical Tanks.

Types

- Acid tanks

- Blend and mix tanks

- Buffer tanks

- Circulation tanks

- Feed tanks

- Filtrate tanks

- Holding tanks

- Jacketed tanks

- Pressure vessels

- Pump tanks

- Reactors

- Receiver tanks

- Solution tanks

- Solvent tanks

- Storage tanks

- Stripper/Scrubber Columns

- Surge tanks

Similarly, there are many other uses of tanks. Application

Chemical process tanks have found applications in plenty of industries. These include:

- Textile

- Leather

- Paper

- Plastic

- Steel

- Oil and petrochemicals

Harsh challenges

The process tanks witness harsh chemical and manufacturing processes. Therefore, they should be resistant to corrosion and harsh weather, for example, rainfall and cyclone.

Chemical storage tanks

As a businessman, if you plan to procure a chemical storage tank for your manufacturing process, it’s important to the chemical you are planning to store. Here is a classic example of a lack of knowledge. Many think that a tank that stores water and other edible fluids is competent to hold industrial chemicals. This is a wrong perception. Therefore, it’s important to buy the right product. And a tank is a tank? This is not true always!

Why do industries require special tanks?

A chemical storage tank has various uses, for instance, storage, mix, and transport of a wide range of chemicals. You might have seen similar tanks at chemical factories, surface treatment plants, pharmaceutical companies, textile factories, etc.

Different materials for different chemical

A few chemicals require a different type of material for storage. Let’s understand it with an example, highly oxidizing materials, including sulfuric acid. It can’t be stored in a normal tank as oxidation degrades the tank. It can cause a dangerous situation. Experts are of the opinion that to store such chemicals, special-purpose materials i.e. PP, and HDPE is a must.

Why tanks are necessary?

Don’t forget that chemicals that produce sludge, including ferric, alum, and polymer offer many challenges. The sludge-producing chemicals require tanks with a few specific features. It should drain completely. The fuming tanks require bottom full drainage. Why is it like that? There’s a logical reason behind this. A similar kind of design doesn’t require a person to enter the tank for cleaning.

Storage of different chemicals

These special signed tanks store several types of hazardous industrial chemicals, these include below mentioned few among others:

- Hydrochloric acid

- Sodium hypochlorite

- Sodium hydroxide

- Sulfuric acid

- Urea exhaust

- Petrochemical exhaust

- Ferric chloride

- Soda ash sodium carbonate

- Industrial wastewater

Choose the perfect manufacturer

As chemical processes require specific chemicals, never compromise with quality. The name and fame of the manufacturer are important. Few manufacturers in Ahmedabad with rich experience in manufacturing chemical process tanks and chemical storage tanks have hands-on experience.