Tag: Hot dip galvanization

In this manufacturing industry-centric blog, we are going to focus on an important subject: costing of galvanization plants and their technology. Many of you have this perception that hot dip galvanizing technology is expensive, it’s beyond the reach of the normal manufacturer. In the ensuing section, we will highlight many relevant issues.

At the outset, it makes sense to understand the hot dip galvanization as it will help you to relate to the subject better.

Learning about the Hot dip galvanization

Simply put, the hot dip galvanizing process is a unique scientific process wherein steel/ metal objects are immersed into molten lava of zinc. As a result, a scientific reaction takes place. The metallurgical reaction forms a coating over the object. Subsequently, the metal develops numerous properties and features, primarily resistant to corrosion.

The formation process

This is a sophisticated process that helps in the process of forming an iron zinc alloy between the iron matrix and the outermost pure zinc layer. As a result of the scientific process, the iron-zinc alloy layer is formed on the surface of the object.

Process of Coating

From the basics, let’s now move to the process of hot dip galvanizing technology. The below information will give you significant information about the process:

Workpiece → Degreasing → Water Washing → Pickling → Water Washing → Dipping Helping Solvent → Drying and Preheating → Hot-dip Galvanizing → Finishing → Cooling → Passivation → Rinsing → Drying → Inspection

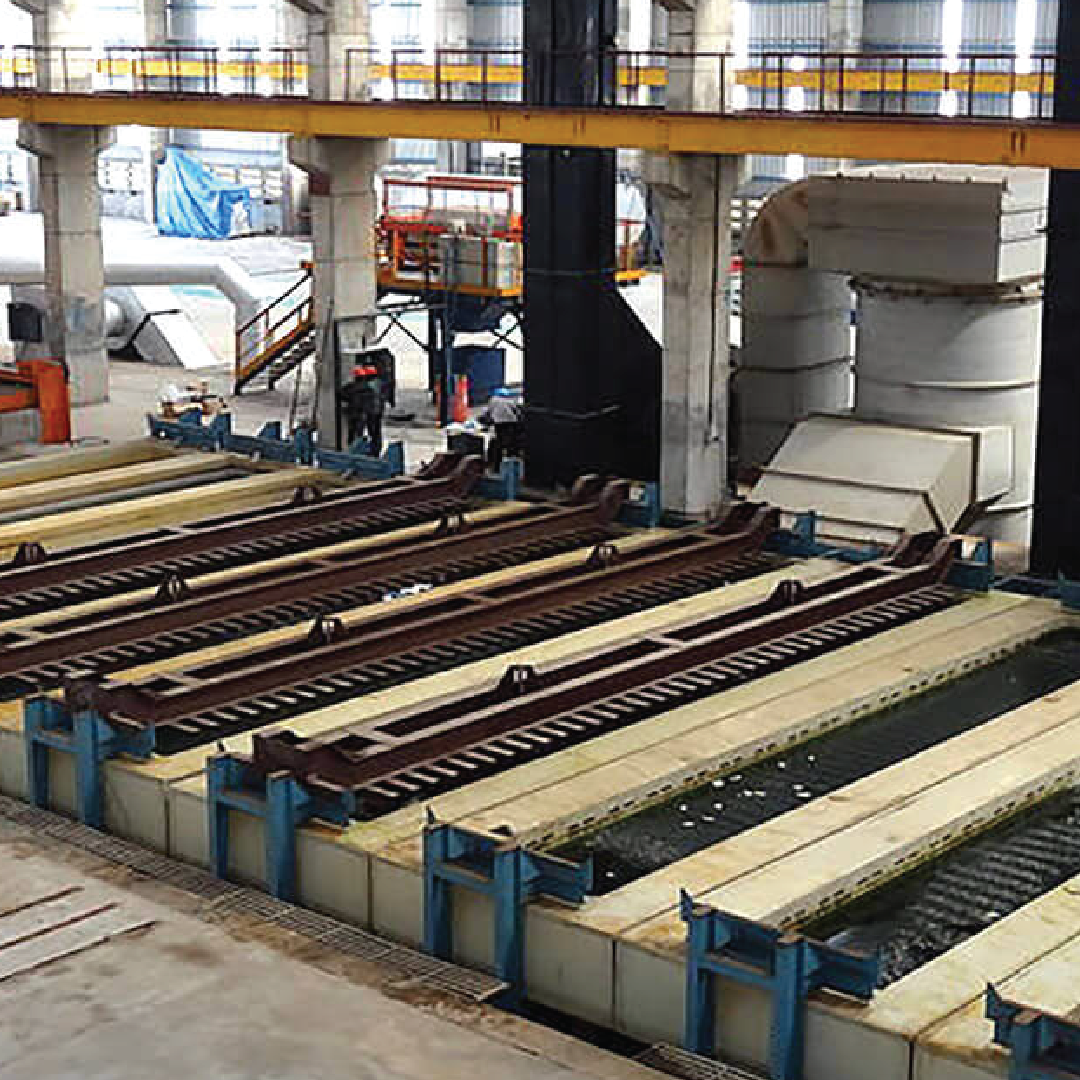

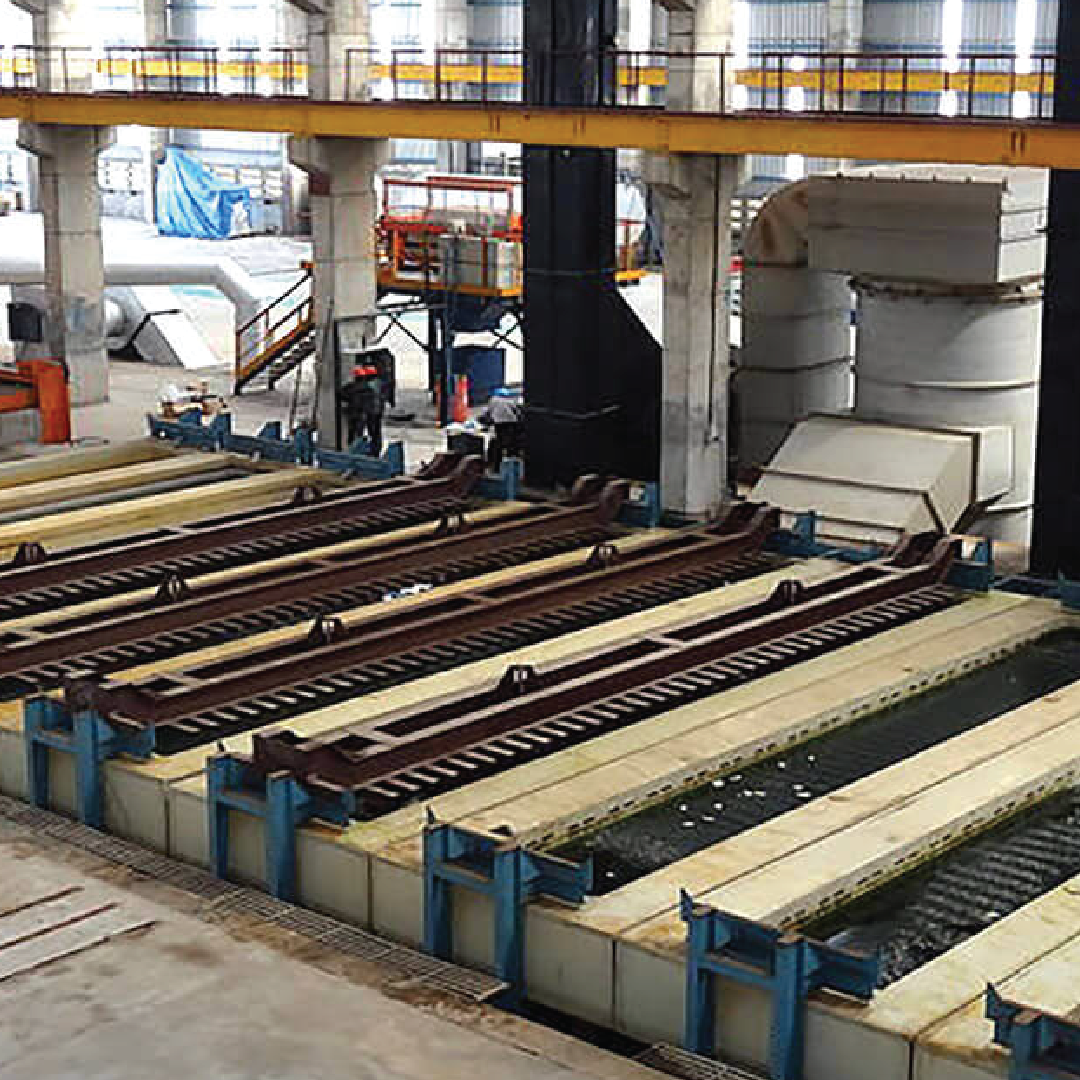

Hot dip technology

Let’s now move towards the hot dip galvanizing technology. The sophisticated process comprises scientifically proven steps and stages combined with the latest technology. It comprises:

- Degreasing

- Pickling

- Immersion flux

- Drying and preheating

- Hot dip galvanizing

- Finishing

- Passivation

- Cooling

- Inspection

Hot dip galvanization costly?

From the fundamentals, let’s now shift our focus to the most crucial subject of the blog.

Is it costly? Is it beyond the reach of small and medium manufacturers? Many of you might have struggled with similar questions. In the following section, we are going to solve the complex subject.

This needs to be understood with an example. According to research the overall cost of protecting a steel object or frame throughout its life depends on numerous factors, including the cost of paints, coatings, frequency of painting, any other relevant treatment, the life of the object, etc.

It has been observed that over a period of 20-25 years, the cost of paint will almost be around 70% more than the cost of galvanizing. While hot-dip galvanization technology offers a durable and maintenance-free life of the product.

Considering the lifetime costs, the latest system of galvanization proves to be considerably cheaper in comparison to other systems of galvanization. In other words, it costs less, lasts longer.

When you buy a galvanized material like a galvanized gate, you will have to pay more than an ordinary metal gate. However, the corrosion-resistant property and features of galvanization make it highly durable. It is worth investing in galvanization.

For further information about the cost of galvanizing plants and its technology, you can connect a few leading hot dip galvanizing plant manufacturers. In this era of technology, finding an established galvanization plant is just a click away.

Browse search engines with keywords like hot dip galvanization. The search engine result page will come up with web pages. Click on a few pages. Browse the website properly.