Tag: galvanizing plant

The galvanizing industry has experienced multiple transformations in the past few decades, with a notable shift towards automation. The need for efficient, reliable, and innovative galvanizing solutions has increased with the demand for long-lasting, corrosion-resistant materials.

In this blog, we will understand and explore the future of Automatic Hot Dip Galvanizing Plant and we will also understand the role of Galvanizing Plant manufacturers in driving these future advancements.

Introduction to Hot Dip Galvanizing Technology

The method of hot dip galvanizing provides a layer of zinc to steel or iron to prevent corrosion. To form an effective barrier against rust, the metal component is dipped into the molten zinc. For enhancing the durability of metal products, this automated approach is frequently used in an array of industries, like industrial, automotive, and construction.

The evolution of Galvanizing Technology

The technology used in the galvanization process has improved considerably over time. The evolution has taken place to lower costs, maximize productivity, and improve the caliber of the galvanizing process.The automatic galvanizing plants are the solution for all these problems. They serve many benefits than the traditional system.

Benefits of Hot Dip Galvanizing Plants

The use of Automatic Hot Dip Galvanizing Plants has provided number of benefits like:

- Enhanced efficiency

Automatic galvanized plants are designed in a way which will help to maximize efficiency by automating various stages of the galvanizing process.

- Improved Quality

The automatic process ensures consistent results like high-quality zinc clothings. The high-quality coatings provide durability and better corrosion resistance.

- Improved Quality

The automated process gives precise control over the quality to ensure high-quality coatings and to prevent corrosion for a long time.

- Cost savings

Even though the initial investment for installing the automatic plant is high, there are long term cost savings from this plant.

- Environmental benefits

The automated plants are modern and are designed in a way that they are environment-friendly. They have a control system which controls emissions which in turn reduces the environmental hazards.

The role of Arvind Corrotech in Advancing Galvanizing Technology

Arvind Corrotech, is a leading Galvanizing plant manufacturer providing high quality and efficient Turnkey hot dip galvanizing plants and automatic hot dip galvanizing plants. Our company has been at the forefront for bringing advancements in the galvanizing industry. Our plants are designed in a way that they can provide efficient and reliable results to every industry.

- Turnkey solutions

We offer complete turnkey solutions for setting your hot dip galvanizing plants. Our solutions will include everything from design and engineering to installation and commissioning.

- Customisation and flexibility

At Arvind Corrotech we give top priority to quality. We use high-quality materials and components during our galvanizing plant manufacturing to make sure that it performs efficiently for a long time.

- Innovation and Technology

We are committed to continuous innovation and adaptation of new technology. Our plants have control systems and automatic solutions which use modern technology. The innovations that we bring help in improving the quality of the galvanizing process.

The Future of Automatic Hot Dip Galvanizing Technology

The future of this technology looks promising, with several new trends and advancements.

- Advanced Automation and Robotics

As in today’s generation technology is continuously evolving, thus we can expect to have greater levels of automation and even the integration of robotics in this industry with time.

- Adaptation of IoT

The adaptation of IoT or industry 4.0 technology can help in bringing advancements in the galvanizing industry. This adaption will help in the decision making process.

- Sustainable practices

To provide environmental sustainability, the future of automatic hot dip galvanizing plants can have advanced control systems, energy-efficient technologies and also waste reduction strategies.

- Digital Twin Technology

This technology involves creating a duplicate or a replica of a same physical plant. This technology if incorporated in the future will allow real time monitoring leading to improved performance.

- Customisation and Flexibility

To provide great adaptability by various industries, the future galvanizing plants will be designed in a way to fit a wide range of products with different sizes and shapes.

Conclusion

The future of automatic galvanizing plants is very promising and bright. With a number of advancements happening in this field, there will be a huge transformation in this industry. We at Arvind Corrotech, are shaping the future of the galvanizing industry to ensure that every client who invests in the galvanizing plants achieve their goals with confidence.

For the industries who are looking to invest in galvanizing plants, now it is the right time to improve your production capacities and quality of your products, with cost savings and latest innovations with us.

Contact us today, to learn about the wide range of galvanizing solutions and stay ahead in your industry!

Businesses aiming at improving the efficacy and quality of their galvanizing procedures should think about investing in automatic hot dip galvanizing plants. The latest technology in automatic plants enables the automation of many galvanizing procedures, resulting in greater output and uniform outcomes.

Understanding the components of these plants is very important for making decisions regarding implementation and operation. In this blog, we will understand the essential components of Automatic galvanizing plants, and also the function and benefit of each component.

-

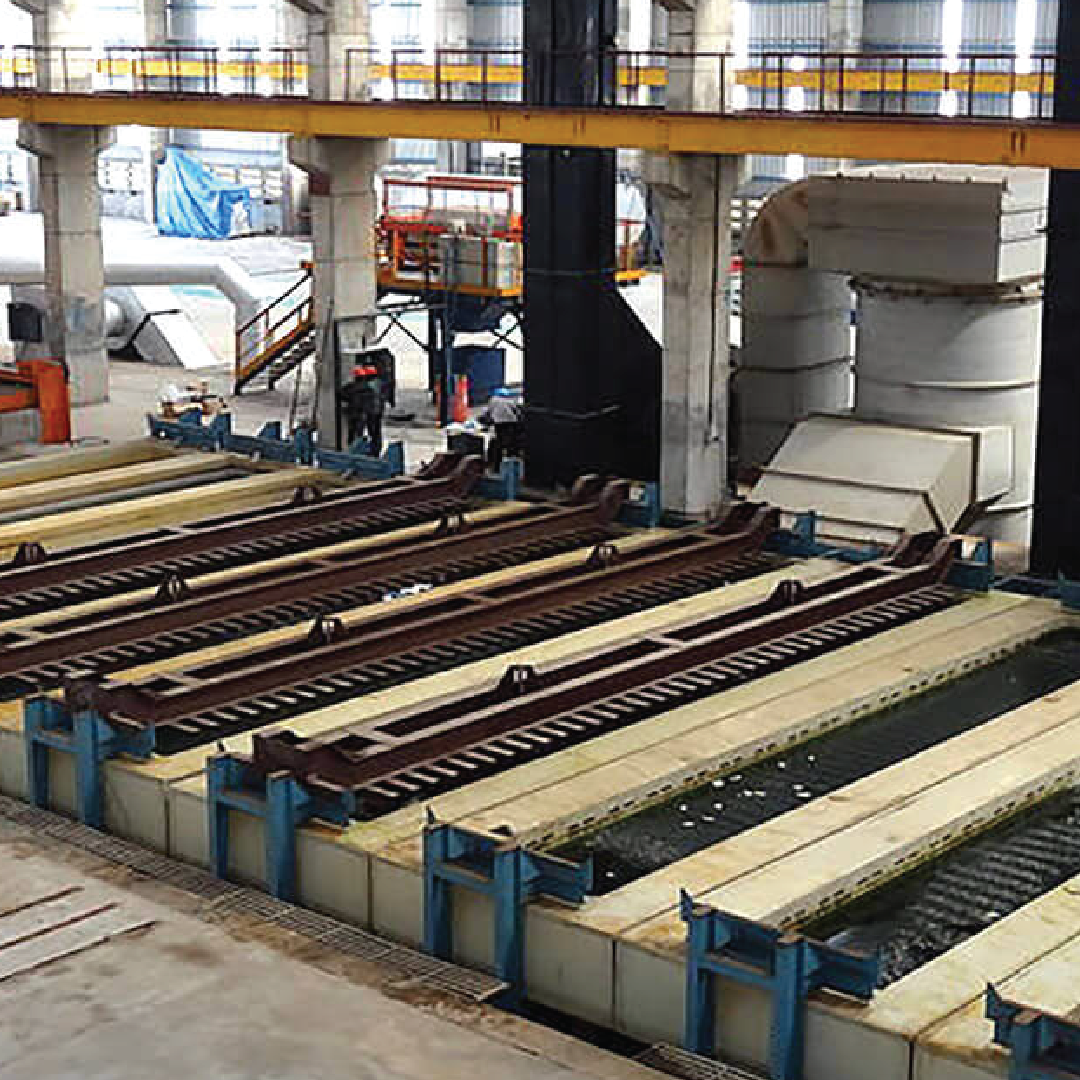

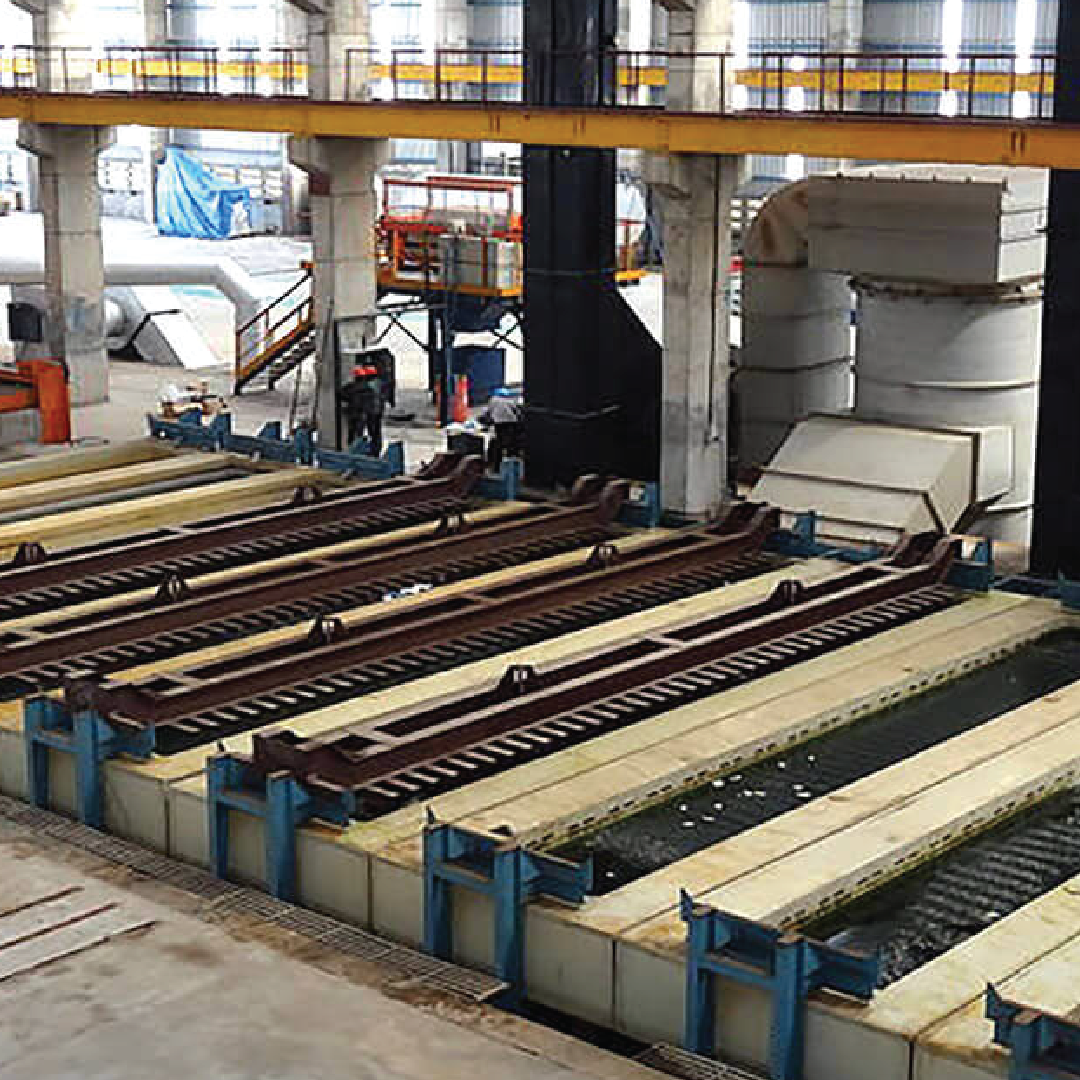

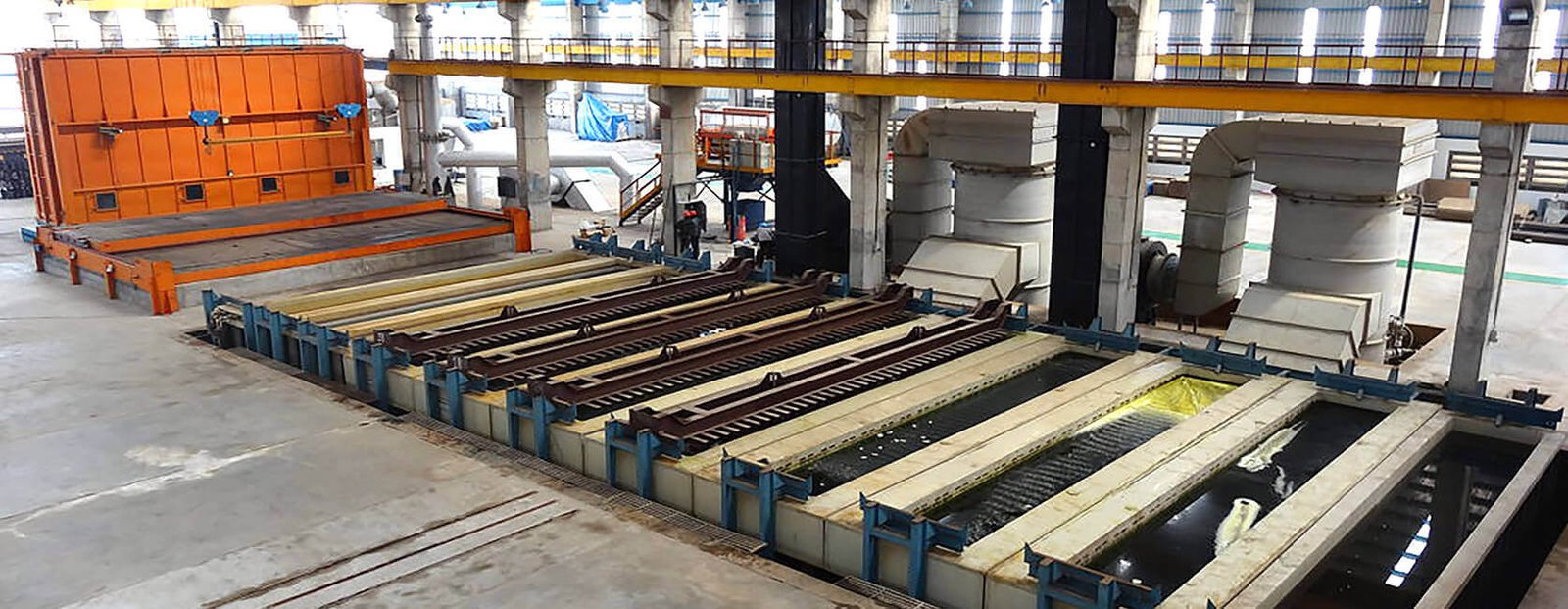

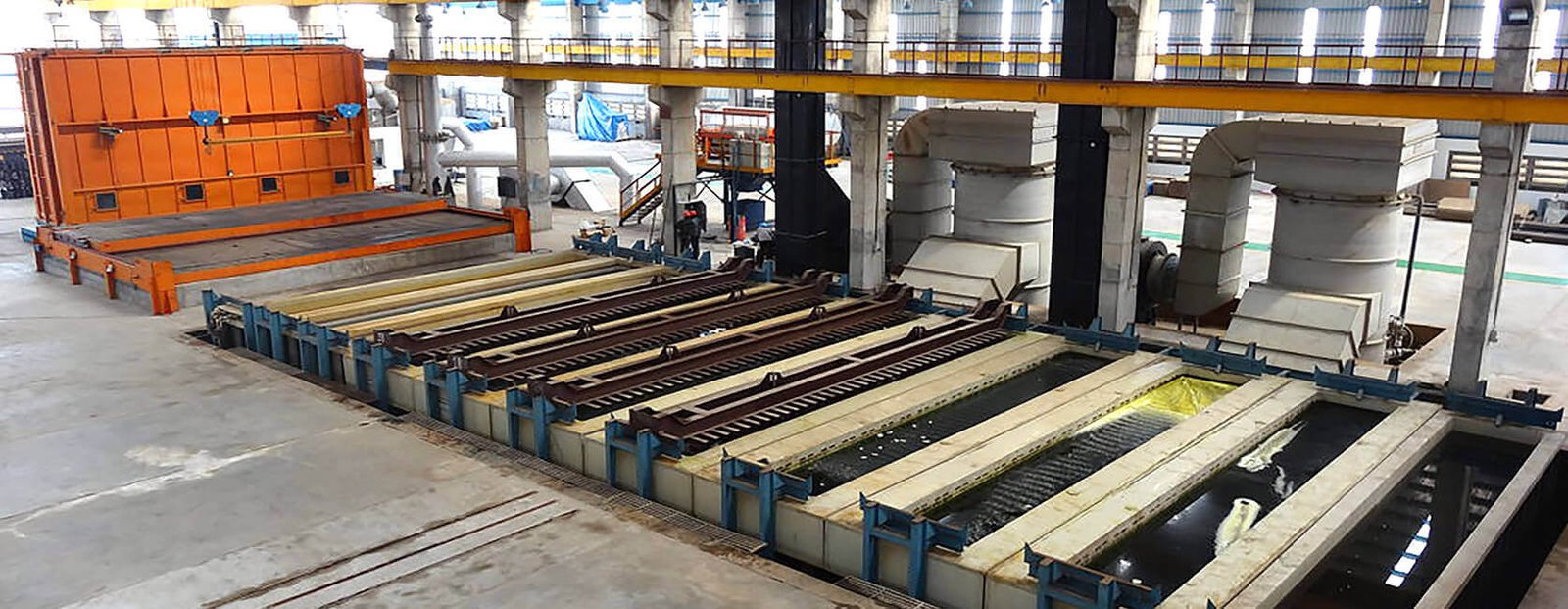

Pre-Treatment section

The first stage in the galvanizing process is the pre-treatment section. This stage is important for preparing metal or in simple terms steel products for coating. The things which are included in this section are:

- Degreasing Tanks

These tanks help in removing the excess oil, grease, and other oily substances which are present on the steel surface. A completely clean surface is very essential before the zinc coating.

- Pickling Tanks

These tanks are filled with acid solutions and help in removing rust, scale or any such oxide from the steel. The use of this tank provides a proper smooth and clean surface for galvanizing.

- Rinsing Tanks

After pickling the steel with acid, the steel is again rinsed in the tank to remove the leftover acid from the surface.

The benefits of the Pre-Treatment section are:

- Provides clean and smooth steel surfaces.

- Will help in giving the proper zinc coating.

- Will improve the quality of the final product.

- Fluxing section

In this section, the clean steel is dipped into a flux solution, which is simply, ammonium chloride. This step is important as it prevents oxidation. The different components of this section are:

- Flux tanks

These tanks have flux solutions, which help in promoting the bond of zinc and steel.

- Drying ovens

Steel parts after fluxing are dried properly in this oven to remove any sort of residual moisture and to ensure uniform zinc coating.

The benefits of the fluxing section are:

- It helps prevent oxidation.

- It helps in providing a strong bond between iron and zinc.

- It helps in improving the quality and durability of the galvanized coating.

- Galvanizing Kettle

This is the most important component of the galvanization process. It has molten zinc which has a temperature around 450°C.

The different components of this include:

- Kettle

The kettle which is used is made up of steel and has ceramic linings, it is used to hold molten zinc for the dipping process.

- Heating System

This system helps in ensuring that the zinc is at the appropriate temperature which is very important for effective galvanizing.

- Dipping mechanism

This mechanism is used for raising the steel parts into and out of the molten zinc, to provide even coating.

The benefits of Galvanizing Kettles are:

- It helps in providing uniform zinc coating.

- It increases corrosion resistance.

- It ensures the durability of the steel products.

- Cooling and Quenching section

After coating the steel parts with zinc, the parts need to be cooled and solidified. This section of the galvanizing process includes:

- Cooling tanks

In this tank, the galvanized steel is cooled using either water or air to solidify the zinc coating properly.

- Quenching tanks

This tank is mostly filled with passivation solution, to enhance the appearance and corrosion resistance property of the zinc coating.

The benefits of the Cooling and Quenching section include:

- The rapid cooling helps in solidifying the zinc coating.

- The passivation which is provided helps in improving corrosion resistance and appearance.

- This section provides durability to the galvanized products.

- Post-treatment section

This section involves additional processes, to improve the quality and finish of the galvanized products. The processes involved are:

- Inspection and finishing

The automated galvanizing plants, in this process, inspect the galvanized products to ensure that there are no defects or uneven coating. Finishing the product includes removing the excess zinc and also adding protective coatings.

The benefits of the Post-treatment section are:

- This section ensures that there is no defect in the product.

- It helps in improving the appearance and durability of the products.

- It prepares the product for safe transportation.

- Control systems

There are advanced control systems which are integrated into the automatic galvanizing plants, to ensure precision and efficiency.

- Programmable logic controllers

These controllers control the entire process from pre-treatment to post-treatment ensuring that each stage is operating correctly.

- Monitoring systems

These systems provide real-time data based on process parameters, which allows adjustments to maintain the optimal temperature.

- Safety systems

They help in protecting the workers and different instruments from any potential hazard.

Benefits of control systems

- It helps in improving the operational efficiency.

- It provides consistent quality and adherence to standards.

- Provides safety and reduces the risk of accidents.

Conclusion

Investing in a proper Automatic Galvanizing plant or a Turnkey hot dip galvanizing plant can provide many advantages like increased efficiency, consistent results, and enhanced safety. Understanding all the key components helps the businesses to make proper decisions about the implementation and operation.

We at Arvind Corrotech, are leading galvanizing plant manufacturers and provide all the solutions according to your needs. By using advanced technology and automation, hot dip galvanizing plants can improve your production capabilities and provide you with high-quality galvanized products.

In this manufacturing industry-centric blog, we are going to focus on an important subject: costing of galvanization plants and their technology. Many of you have this perception that hot dip galvanizing technology is expensive, it’s beyond the reach of the normal manufacturer. In the ensuing section, we will highlight many relevant issues.

At the outset, it makes sense to understand the hot dip galvanization as it will help you to relate to the subject better.

Learning about the Hot dip galvanization

Simply put, the hot dip galvanizing process is a unique scientific process wherein steel/ metal objects are immersed into molten lava of zinc. As a result, a scientific reaction takes place. The metallurgical reaction forms a coating over the object. Subsequently, the metal develops numerous properties and features, primarily resistant to corrosion.

The formation process

This is a sophisticated process that helps in the process of forming an iron zinc alloy between the iron matrix and the outermost pure zinc layer. As a result of the scientific process, the iron-zinc alloy layer is formed on the surface of the object.

Process of Coating

From the basics, let’s now move to the process of hot dip galvanizing technology. The below information will give you significant information about the process:

Workpiece → Degreasing → Water Washing → Pickling → Water Washing → Dipping Helping Solvent → Drying and Preheating → Hot-dip Galvanizing → Finishing → Cooling → Passivation → Rinsing → Drying → Inspection

Hot dip technology

Let’s now move towards the hot dip galvanizing technology. The sophisticated process comprises scientifically proven steps and stages combined with the latest technology. It comprises:

- Degreasing

- Pickling

- Immersion flux

- Drying and preheating

- Hot dip galvanizing

- Finishing

- Passivation

- Cooling

- Inspection

Hot dip galvanization costly?

From the fundamentals, let’s now shift our focus to the most crucial subject of the blog.

Is it costly? Is it beyond the reach of small and medium manufacturers? Many of you might have struggled with similar questions. In the following section, we are going to solve the complex subject.

This needs to be understood with an example. According to research the overall cost of protecting a steel object or frame throughout its life depends on numerous factors, including the cost of paints, coatings, frequency of painting, any other relevant treatment, the life of the object, etc.

It has been observed that over a period of 20-25 years, the cost of paint will almost be around 70% more than the cost of galvanizing. While hot-dip galvanization technology offers a durable and maintenance-free life of the product.

Considering the lifetime costs, the latest system of galvanization proves to be considerably cheaper in comparison to other systems of galvanization. In other words, it costs less, lasts longer.

When you buy a galvanized material like a galvanized gate, you will have to pay more than an ordinary metal gate. However, the corrosion-resistant property and features of galvanization make it highly durable. It is worth investing in galvanization.

For further information about the cost of galvanizing plants and its technology, you can connect a few leading hot dip galvanizing plant manufacturers. In this era of technology, finding an established galvanization plant is just a click away.

Browse search engines with keywords like hot dip galvanization. The search engine result page will come up with web pages. Click on a few pages. Browse the website properly.

In this business-centric blog, we will emphasize an extremely important subject, galvanizing plants. A wide range of issues will be covered ranging from basic definitions to benefits of the industrial process.

Before we take a deep dive into the industrial subject, let’s make an effort to understand the industrial term which is our defining socio-economic life.

Learning about galvanization

What is galvanization? For many of you, it is a new term. Galvanization is a scientific process wherein a thin layer of zinc metal is applied to iron/steel-made objects to prevent them from corrosion.

Hot-dip galvanizing plant

According to experts, the most common method for galvanization is hot-dip galvanizing. Under this popular process, steel sections are dipped in a bath of molten zinc. The zinc layer acts as a shield and protects the metal from corrosion and in turn, increases its durability many times. Hot-dip galvanizing plants in Ahmedabad are tailor-made for the purpose. Galvanizing plant manufacturers are using the latest machines and tools to manufacture an excellent plant.

The three steps of the hot dip galvanizing plant

The hot dip galvanizing process comprises three major steps:

- Surface preparation

- Galvanizing

- Inspection

How does the zinc layer protect iron structures?

There is a scientific reason. As zinc metal is hyperreactive, it reacts with air to form a hard layer of zinc oxide on the metallic structure. This layer works as a protective shield and prevents air from passing through it. Subsequently, protecting the iron/ steel from corrosion.

From basics, let’s now shift our focus to important reasons why industries galvanize steel?

Durable: Galvanization has been transforming many industries with its incredible feature. It multiplies the durability of the product many times.

A worthwhile investment: Initially it appears expensive, in the long run, it is a worthwhile investment. A galvanized structure lasts around 100 years.

The coating thickness depends upon the gauge of the metallic structure. The thickness of galvanization can be measured easily, whenever you wish. It is a non-destructive method…

Scientific process: Zinc oxide that acts as a protective layer occurs through a proven scientific process. It’s a natural metallurgical reaction.

Galvanizing is visible: Right from the beginning, galvanized steel structure starts showing its significance. Therefore, galvanizing is visible. It starts working from day one.

Complete coverage: Hot dip galvanizing helps in creating a very strong bond between zinc and steel. Thus it provides complete coverage, amazing strength, and durability. Owing to these features, the iron-made structures remain protected even during harsh weather conditions.

Summary

Hot dip galvanized steel is engulfing all of us in many different forms. It is all around us. Numerous companies, industries, sectors, etc. are leveraging the phenomenon, including automobiles, railways, power transmission, windmills, infrastructure, etc. Over the years, it has become integral to our lifestyle, and rightly so.

Buy the galvanization plant from Arvind Corrotech

Arvind Corrotech is an industry leader offering full-spectrum galvanization solutions. Our quality-driven product range includes Turnkey Hot Dip Galvanizing Plants, Pulse Fired High-Velocity Furnace, Process Tanks, Chemical Storage Tanks, and pollution control equipment.

If you are on the lookout for anything related to pollution control equipment, then end your search with Arvind Corrotech. Let’s connect for a mutually beneficial collaboration.

Pickling is a metal surface treatment that is used for the purpose of removing impurities like stains, rust, or scale from copper, alloy, and other metals. Pickle liquor, which is an acid-based solution is used to eliminate the impurities from the surface. Metal can contain impurities that may affect the quality of the product or further processing of it like plating or painting.

Pickling is the most preferable method of removing rust and mill from structural shapes, beams, and plates in workshops, keeping the cost of removal budget-friendly. When the process of pickling is done impeccably, this method creates a surface that will have long paint life with various coatings.

There Are Six Main Pickling Methods, Which Includes –

- Sulfuric or hydrochloric acid pickling

- Phosphoric acid pickling

- Sulfuric acid-sodium dichromate pickling

- Alkaline pickling

- Footner pickling

- Electrochemical treatment

These are some of the most popular pickling methods and they are used depending on the nature of the rust and scale to be removed, the materials that are used for the manufacturing of the articles, the desired pickled surface, and the cost and availability of pickling material and equipment.

Pickling Tank

A picking tank is a kind of tank that is used for the process of metal surface treatment containing acid where the metal is immersed in the pickling acid in order to scale off the oxide/rust from the product which is being treated.

How The Pickling Tank Designed?

- It is designed as per the standard DVS 2205.

- It has good weld joints for making it leakage proof.

- It has good abrasion resistant power.

- It is made with reinforced steel.

What Is The Size Of Pickling Tanks?

Small tanks have a capacity of a few hundred liters while the big tanks have a capacity of over 20,000 liters. These tanks are built to the size of metal objects which will be treated in the tank.

What makes Corrotech one of the leading and reliable manufacturers of pretreatment and post-treatment tanks for galvanizing plants?

Corrotech is one of the leading suppliers and manufacturers of Pickling tanks in India and also other types of pre-treatment and post-treatment tanks for galvanized plants. We use RITA 3 (Roechling Integrated Tank Design), which is a German Software to design the tanks and we adhere to manufacturing practices laid in the DVS (German Welding Society) Technical Codes. Corrotech has achieved a unique ability in FOLD bending the PP sheets providing more durability and strength to the tank. Corrotech strictly adheres to the welding norms laid by the German Welding Society and ensures superior quality tanks. Corrotech is immensely proud to be the company in the world to weld the main body and the end walls of the tank using the “Butt Fusion” technique which gives long life to weld seams which eliminates the risk of tank failure or leakage. At Corrotech, we fabricate the support frame structures using Rectangular Hollow Sections (RHS) and coat them with FRP to resist acid attack. The steel is procured as per IS 4923 – 1997 or any other international standard as per the requirements of the contract. The welds are prepared as per AS 1554 and the weld type is the continuous fillet.

The top features of the tanks manufactured by us are –

Manufactured using Homopolymer Polypropylene or Copolymer Polypropylene or Fiber Resin Plastic

- Sheets are welded using German Wegner Welding Machine according to DVS norms which eliminates leakage and ensures a long lifespan.

- 100% leak proof welding.

- Tanks have 900C FOLD bending at the bottom corners

- The raw material is procured from global vendors; Rochling, Germany, Reliance, India, etc

- Environmentally friendly design.

- Superior design

- Lifting arrangement.

Benefits To Have The Pickling Tank In Your Galvanizing Plant:

- All the pickling tanks required exactly no maintenance.

- All the tanks are made easy to repair and modify.

- All the tanks have a good life span, and they have greater strength at the corners.

- They are resistant to rust, corrosion, and chemicals as well.

Benefits which our tanks offer to the customers –

- Increased productivity

- Low production cost

- Better surface quality

- Corrosion-resistant

The highly reliable pre-treatment tanks consist of the pickling tanks and other tanks as well. Considering that you may have the process tank, degreasing tank, rinsing & de-fluxing, and pickling tank. They are mostly famous for their robust structure and modular design. You can get a comprehensive solution for the pickling tanks with the proper structure and special coatings

The Furnace requires low upkeep costs and is exceptionally dependable since there are the least quantities of burners prompting the least prerequisite of extras. The Pulse Fired High-Velocity Furnace is used in the galvanized plant, as it is designed for the maximum heat transfer in minimum fuel. There are several galvanizing plant manufacturers, make the furnace among the pre-process tank, Polypropylene Tank. The furnace is viable with various fuels like Oil, LPG, and Natural Gas and it is used to heat the metal with the burners work with low overabundance air with high fire the outflow levels likewise diminish significantly.

What Are The Features Of the Pulse Fired Furnace?

Arvind Corrotech makes the automatic furnace. For the galvanizing plant, it is necessary to heat the material, and if you don’t monitor it then it will be not useful.

- The furnace has a fully automatic operation, along with the auto flame monitoring and ignition system.

- The furnace has the system to use any kind of fuel, including oil like HSD and LDO, duel fuel like oil& gas, and gas like LPG and PNG.

- The furnace has made with high-density ceramic fiber so that it can deliver good fuel efficiency.

- The furnace needs good air combustion during the process so it is made with precise control.

- There is a kettle attached to the furnace and it is installed with the protection to the furnace.

How Does The Pulse Fired High-Velocity Furnace Work?

The Pulse Fired High-Velocity Furnace is made for the maximum heat exchange purpose in minimum fuel input. The operation will be succeeded with the high-velocity technology. For the proper work of the furnace, there is the most efficient firing setting and ideal operation condition. The good qualified and experienced engineers make the furnace to maintain easily. The pulse fired furnace can be used with an improved temperature, good kettle life, and improved fuel capacity.

As we have watched, the guideline is straightforward. Notwithstanding, the real plan of an individual heater is intricate, considering such factors as exhibition width, burner size, exact burner area, and ideal gas speed for safe warmth move levels with a shirking of harm to protecting materials. The furnace works as per that, also there are several other components considered for the good heating.

For the maximum heat transfer and minimum fuel input, the pulse firing furnace setup is done by the expert. It operates the burner for the maximum fire. The maximum heat exchange can be done with high-velocity technology. The furnace is operated in the ideal condition to utilize the fuel in a good way and so you can transfer the heat at high velocity.

High-speed gas or oil-powered burners are mounted into one, whatever you want to use you can use. Simultaneously, these oil and gases assimilate the exceptional neighborhood burner heat, rearranging it equally around the outskirts of the pot. The outcome is high working productivity and uniform heat transfer.

Everybody perceives the estimation of ability and the sort of involvement that must be picked up by placing a wide scope of burners into the field throughout an extensive period. Yet, the hypothetical component is additionally basic. High-speed heaters contrast broadly in pot measurements and required creation rates.

How does Furnace work with Some Factors?

- Temperature Control

The main factor to consider is – temperature control. Arvind Corrotech makes furnace automatic. That is auto-monitoring helps for temperature control. All in all, it is basic to run the burners at their high fire for as incredible an extent and for the time that is important to meet the capacity of the furnace.

The molten point of the zinc is detected by a thermocouple and an electrical sign, and that is already set in the furnace.

- Efficiency

Now, it is maybe worth expounding on one of the more fundamental aspects as per the working process. With the framework of the pulse furnace, you can increase the capability of the galvanizing process. This viewpoint is the inference of framework productivity dependent on a determined vent temperature.

At the point when the zinc temperature dips, it makes the uniforms. It is used for the dross formation. The furnace is used for high-velocity fuel circulation. The pulsed fired high-velocity furnace gives long kettle life. It is free of maintenance, and it can be operated with low excess air.

Last Thought,

With the standard framework, tough material, and proficient heater the pulsed fired high-volume furnace is good to use in zinc galvanizing plant.

There are several hot dip galvanizing plant manufacturer Ahmedabad India, provide the galvanizing plant. With the numerous years of experience in the field, Arvind Corrotech is the leading turnkey hot dip galvanizing plant supplier.

The galvanizing plant is with the aid of using par one of the maximum ecological strategies of galvanizing the metal with the zinc. The process is done to make the meta corrosion-free and make it durable for a long time. The manufacturerus all in one package with the several units and provide the hot dip galvanizing. With the packages in which metal are uncovered to severe atmospheric conditions. The hot dip galvanizing firms make these products to galvanized with the zinc.

- Metal Pipes

- Electrical Poles

- Road Side Barriers

- Steel Towers Used For Electrical Transmission

- Cable Trays

- Steel Towers Used For Mobile Towers

- Fasteners

- Hardware Industrial Items

This plant is a genuine production system throughout some steps of the galvanizing plant. Other pre and post processes should be followed by the plant exporter. A spectrum of the pickling or process tanks used for removing the extra dust, and they consist of the acid or other chemicals.

The tanks are resistant to a wide range of chemicals, also they have great mechanical properties. The tanks are supplied from the exporter Ahmedabad India available in the PPH pp and pp-FRP as well. All the storage tanks should be easy to operate, and the tanks should be manufactured in vinyl ester fitted with the granite.

All the tanks are available in various shapes and sizes that suit every batch of the pickling material. The things such as sheet metal components, wire, pipe mills, and cr mills can be pre-processed before galvanizing plant.

Components To Be Used For Galvanizing Plant:

- Pre-Treatment Tanks

- Pulse Fired High-Velocity Furnace

- Zinc Kettle

- Acid Fume Extraction System

- Flux Heating System

- Acid Storage Tanks

- Effluent Treatment Plant

The zinc galvanizing process can be followed step by step by using the component listed above.

The Hot Dip Galvanizing firms make the galvanizing plants that can help you in galvanizing with the:

- Rapid Application

- Reliability

- Proper Mechanical Resistance

- Lower Production cost

- Easy Maintenance & Testing Of Galvanizing Quality

- Ultimate Protection

At Last,

The material can be galvanized by using the perfect hot dip galvanizing plant if it is employing top quality that credits all the components of the plant. Besides, to check the associated with the galvanizing plant, you should consider the top manufacturer, supplier, or exporter.

The enormous and remarkable economic challenges have introduced the need to utilize limited resources in an efficient and effective manner. The impact of currency devaluation along with globalization and environmental concerts are changing the overall governance to a high extent.

Why Make Generous Usage of Hot Dip Galvanizing Plant?

High technological advances have enabled some exclusive ways of deploying services in a cost-effective and timely manner. The generous usage of hot dip galvanizing plant is a great example. Yes, along with having a firm grip on preventing corrosion; it has proved to be an environmental friendly and cost effective solution.

Galvanizing plants have made it easy for governments to take best decisions for building and expanding their infrastructures to remain competitive in:

- Tourism

- Transportation

- Economy

Turnkey Hot Dip Galvanizing Plant Helping to Prevent Corrosion

Governments continue to focus on expanding militaries and managing political systems to expand national infrastructures. To ensure that these facilities operate at optimal level, effort is being geared to preserve them from corrosion,turnkey hot dip galvanizing plant has proved to be of great help.

Such plants will prevent controlling corrosions to a high extent, thus ensuring maximal services to citizens. Top hot dip galvanizing firms are adopting the most suitable technological solution to the hazards will truly extent the usefulness of such facilities. Also, it will benefit both the nation.

Painting and Plating Remains No More Effective Today

Generally, painting and plating are common methods used to prevent the ill effects of corrosion. Though partly effective, it will be a good idea to go with a top manufacturer of galvanizing plant. It has proved to be a reliable, cheap and durable method of preventing rusting hence causing less harm to the environment.

In case you are unable to halt to the best decision, better have a detailed discussion with a reliable supplier in Ahmedabad. It will give you an insight to the merits along with methods of maintaining these plants.

Remarkable Benefits of Hot Dip Galvanizing Plants

Want to know what attracts industries towards hot dip galvanizing plants? Below are some remarkable benefits assured by top exporters in India:

- Low cost and less labour intensive

- Highly durable with less maintenance

- High life expectancy of minimum forty years

- Process is simple, controllable and straightforward

With a wide variety of options available in the market, it will become easy to select the most suitable galvanizing plant for your needs.