The Flux Filtration System is of utmost significance in a hot dip galvanizing plant and it plays a prime role in high-quality galvanization and to lower zinc consumption. It is necessary to maintain a balanced chemical composition in the flux tank as fluxes get polluted with the iron ions that get mixed in the flux while processing the material in the flux tank.

Iron has a natural bond to zinc and so it is clearthat dipping the steel material in the flux tank will contaminate the flux. Bonding of iron with a flux solution will result in the generation of excess ash and dross. So, it becomes crucial to control the iron content and pHin the flux to prevent the formation of ashand dross and thereby maintain the efficiency of galvanizingprocess and prevent the expensive zinc from being wasted.

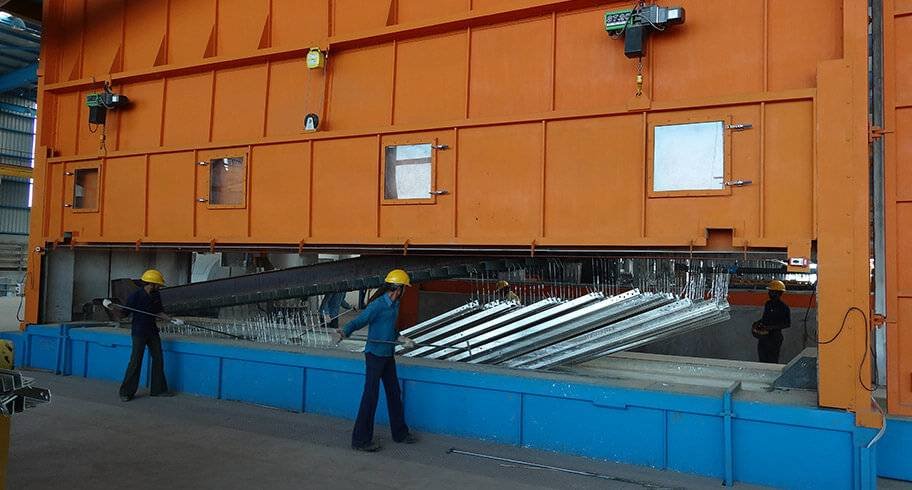

Corrotech provides efficient and fully automatic Flux Filtration System that in a closed loop allows to continuously extract the iron by adding reagents while maintaining the pH of the solution. Less iron is carried to the galvanizing bath and the amount of iron-zinc created is reduced. Filter press is used to extract the oxidized iron without intercepting ammonium chloride and zinc chloride used in flux. Managing the iron abatement allows to balance the content of zinc and ammonium chloride. The clean and chemically balanced flux is again sent back to the fluxing tank. Flux Filtration System by Corrotech is a premium-grade and fully-featured system with robust components for highly reliable flux cleansing.

Equipment Design

- Flux treated in continuous cycle

- Fully automatic system with PLC controls

- Convert Fe2+ into Fe3+ to sludge

- Control of flux process parameters

- Filter system for the sludge

- Dosing pumps with pH & ORP controls

- Mixer for dissolving reagent

- Probes attached with pH & ORP transmitters

Benefits and Cost Savings

- Reduction in zinc consumption

- Cost savings due to low flux consumption

- Low ash and dross formation

- Less rework and rejection in galvanized product

- Environment friendly – Disposal of spent flux is eliminated

Other Products

Explore our premium range of products that are specially fabricated for your galvanizing facility.