Tag: hot dip galvanizing plant

The galvanizing industry has experienced multiple transformations in the past few decades, with a notable shift towards automation. The need for efficient, reliable, and innovative galvanizing solutions has increased with the demand for long-lasting, corrosion-resistant materials.

In this blog, we will understand and explore the future of Automatic Hot Dip Galvanizing Plant and we will also understand the role of Galvanizing Plant manufacturers in driving these future advancements.

Introduction to Hot Dip Galvanizing Technology

The method of hot dip galvanizing provides a layer of zinc to steel or iron to prevent corrosion. To form an effective barrier against rust, the metal component is dipped into the molten zinc. For enhancing the durability of metal products, this automated approach is frequently used in an array of industries, like industrial, automotive, and construction.

The evolution of Galvanizing Technology

The technology used in the galvanization process has improved considerably over time. The evolution has taken place to lower costs, maximize productivity, and improve the caliber of the galvanizing process.The automatic galvanizing plants are the solution for all these problems. They serve many benefits than the traditional system.

Benefits of Hot Dip Galvanizing Plants

The use of Automatic Hot Dip Galvanizing Plants has provided number of benefits like:

- Enhanced efficiency

Automatic galvanized plants are designed in a way which will help to maximize efficiency by automating various stages of the galvanizing process.

- Improved Quality

The automatic process ensures consistent results like high-quality zinc clothings. The high-quality coatings provide durability and better corrosion resistance.

- Improved Quality

The automated process gives precise control over the quality to ensure high-quality coatings and to prevent corrosion for a long time.

- Cost savings

Even though the initial investment for installing the automatic plant is high, there are long term cost savings from this plant.

- Environmental benefits

The automated plants are modern and are designed in a way that they are environment-friendly. They have a control system which controls emissions which in turn reduces the environmental hazards.

The role of Arvind Corrotech in Advancing Galvanizing Technology

Arvind Corrotech, is a leading Galvanizing plant manufacturer providing high quality and efficient Turnkey hot dip galvanizing plants and automatic hot dip galvanizing plants. Our company has been at the forefront for bringing advancements in the galvanizing industry. Our plants are designed in a way that they can provide efficient and reliable results to every industry.

- Turnkey solutions

We offer complete turnkey solutions for setting your hot dip galvanizing plants. Our solutions will include everything from design and engineering to installation and commissioning.

- Customisation and flexibility

At Arvind Corrotech we give top priority to quality. We use high-quality materials and components during our galvanizing plant manufacturing to make sure that it performs efficiently for a long time.

- Innovation and Technology

We are committed to continuous innovation and adaptation of new technology. Our plants have control systems and automatic solutions which use modern technology. The innovations that we bring help in improving the quality of the galvanizing process.

The Future of Automatic Hot Dip Galvanizing Technology

The future of this technology looks promising, with several new trends and advancements.

- Advanced Automation and Robotics

As in today’s generation technology is continuously evolving, thus we can expect to have greater levels of automation and even the integration of robotics in this industry with time.

- Adaptation of IoT

The adaptation of IoT or industry 4.0 technology can help in bringing advancements in the galvanizing industry. This adaption will help in the decision making process.

- Sustainable practices

To provide environmental sustainability, the future of automatic hot dip galvanizing plants can have advanced control systems, energy-efficient technologies and also waste reduction strategies.

- Digital Twin Technology

This technology involves creating a duplicate or a replica of a same physical plant. This technology if incorporated in the future will allow real time monitoring leading to improved performance.

- Customisation and Flexibility

To provide great adaptability by various industries, the future galvanizing plants will be designed in a way to fit a wide range of products with different sizes and shapes.

Conclusion

The future of automatic galvanizing plants is very promising and bright. With a number of advancements happening in this field, there will be a huge transformation in this industry. We at Arvind Corrotech, are shaping the future of the galvanizing industry to ensure that every client who invests in the galvanizing plants achieve their goals with confidence.

For the industries who are looking to invest in galvanizing plants, now it is the right time to improve your production capacities and quality of your products, with cost savings and latest innovations with us.

Contact us today, to learn about the wide range of galvanizing solutions and stay ahead in your industry!

Businesses aiming at improving the efficacy and quality of their galvanizing procedures should think about investing in automatic hot dip galvanizing plants. The latest technology in automatic plants enables the automation of many galvanizing procedures, resulting in greater output and uniform outcomes.

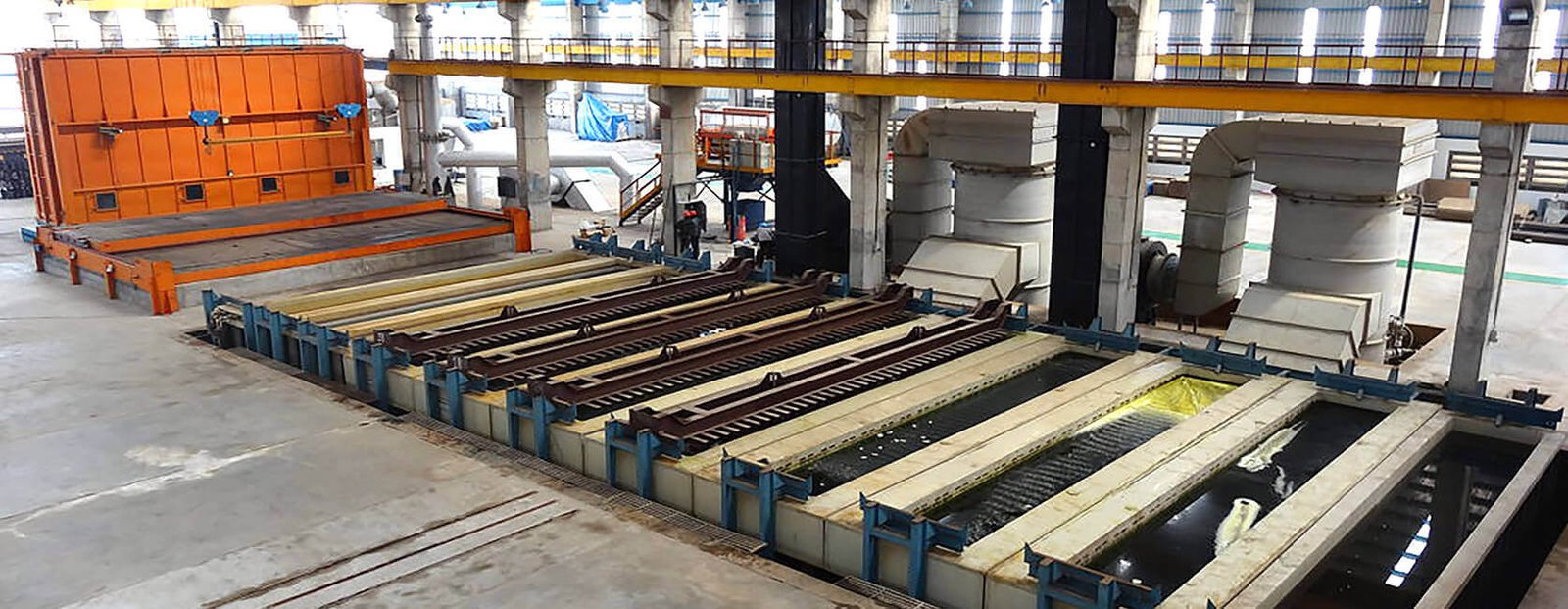

Understanding the components of these plants is very important for making decisions regarding implementation and operation. In this blog, we will understand the essential components of Automatic galvanizing plants, and also the function and benefit of each component.

- Pre-Treatment section

The first stage in the galvanizing process is the pre-treatment section. This stage is important for preparing metal or in simple terms steel products for coating. The things which are included in this section are:

- Degreasing Tanks

These tanks help in removing the excess oil, grease, and other oily substances which are present on the steel surface. A completely clean surface is very essential before the zinc coating.

- Pickling Tanks

These tanks are filled with acid solutions and help in removing rust, scale or any such oxide from the steel. The use of this tank provides a proper smooth and clean surface for galvanizing.

- Rinsing Tanks

After pickling the steel with acid, the steel is again rinsed in the tank to remove the leftover acid from the surface.

The benefits of the Pre-Treatment section are:

- Provides clean and smooth steel surfaces.

- Will help in giving the proper zinc coating.

- Will improve the quality of the final product.

- Fluxing section

In this section, the clean steel is dipped into a flux solution, which is simply, ammonium chloride. This step is important as it prevents oxidation. The different components of this section are:

- Flux tanks

These tanks have flux solutions, which help in promoting the bond of zinc and steel.

- Drying ovens

Steel parts after fluxing are dried properly in this oven to remove any sort of residual moisture and to ensure uniform zinc coating.

The benefits of the fluxing section are:

- It helps prevent oxidation.

- It helps in providing a strong bond between iron and zinc.

- It helps in improving the quality and durability of the galvanized coating.

- Galvanizing Kettle

This is the most important component of the galvanization process. It has molten zinc which has a temperature around 450°C.

The different components of this include:

- Kettle

The kettle which is used is made up of steel and has ceramic linings, it is used to hold molten zinc for the dipping process.

- Heating System

This system helps in ensuring that the zinc is at the appropriate temperature which is very important for effective galvanizing.

- Dipping mechanism

This mechanism is used for raising the steel parts into and out of the molten zinc, to provide even coating.

The benefits of Galvanizing Kettles are:

- It helps in providing uniform zinc coating.

- It increases corrosion resistance.

- It ensures the durability of the steel products.

- Cooling and Quenching section

After coating the steel parts with zinc, the parts need to be cooled and solidified. This section of the galvanizing process includes:

- Cooling tanks

In this tank, the galvanized steel is cooled using either water or air to solidify the zinc coating properly.

- Quenching tanks

This tank is mostly filled with passivation solution, to enhance the appearance and corrosion resistance property of the zinc coating.

The benefits of the Cooling and Quenching section include:

- The rapid cooling helps in solidifying the zinc coating.

- The passivation which is provided helps in improving corrosion resistance and appearance.

- This section provides durability to the galvanized products.

- Post-treatment section

This section involves additional processes, to improve the quality and finish of the galvanized products. The processes involved are:

- Inspection and finishing

The automated galvanizing plants, in this process, inspect the galvanized products to ensure that there are no defects or uneven coating. Finishing the product includes removing the excess zinc and also adding protective coatings.

The benefits of the Post-treatment section are:

- This section ensures that there is no defect in the product.

- It helps in improving the appearance and durability of the products.

- It prepares the product for safe transportation.

- Control systems

There are advanced control systems which are integrated into the automatic galvanizing plants, to ensure precision and efficiency.

- Programmable logic controllers

These controllers control the entire process from pre-treatment to post-treatment ensuring that each stage is operating correctly.

- Monitoring systems

These systems provide real-time data based on process parameters, which allows adjustments to maintain the optimal temperature.

- Safety systems

They help in protecting the workers and different instruments from any potential hazard.

Benefits of control systems

- It helps in improving the operational efficiency.

- It provides consistent quality and adherence to standards.

- Provides safety and reduces the risk of accidents.

Conclusion

Investing in a proper Automatic Galvanizing plant or a Turnkey hot dip galvanizing plant can provide many advantages like increased efficiency, consistent results, and enhanced safety. Understanding all the key components helps the businesses to make proper decisions about the implementation and operation.

We at Arvind Corrotech, are leading galvanizing plant manufacturers and provide all the solutions according to your needs. By using advanced technology and automation, hot dip galvanizing plants can improve your production capabilities and provide you with high-quality galvanized products.

With the advent of modern technology, the process of galvanization has gone through a drastic change. Innovation and technology are enabling companies in the galvanization domain to streamline the process and make them in line with changing market dynamics. Numerous tools and machinery have emerged over the years benefiting the further advancement of Hot Dip Galvanizing plant and process and technology.

You would be surprised to learn about the impact and marks left by galvanization. It’s a blessing in disguise for plenty of industries. Over the years, sweeping changes have taken place. Companies manufacturing steel structures, like cars, crash barriers, power transmission towers, mobile signal towers, wind machines, heavy flyover railings, etc. have been drawing greater benefits from innovative technology.

Flux Heating System is an integral part of galvanization! Before getting into its intricacies, it’s pertinent for you to understand galvanization. Those who are directly or indirectly linked with galvanization and corrosion technology are familiar with the term. Yet, for many, it’s a new term. For the reader’s benefit, here’s a brief definition of galvanization:

What’s Galvanization? Learning Galvanization

This is an intriguing subject! So, how to protect metallic structures from corrosion? A zinc coating applied through a sophisticated process lends durability to iron-made structures. These structures can withstand harsh weather conditions as the anti-corrosive characteristics of zinc resist the damaging elements present in the environment, including moisture, water, salt, etc. The Hot Dip Galvanizing in Ahmedabad is admired across the globe for its quality.

Understanding Hot Dip Galvanization

An exclusive hot-dip galvanization plant is being capitalized by companies to seamlessly accomplish the galvanization process. The sophisticated plant comprises a wide range of technology-driven machines and tools being utilized during the process. Every machine and tool has a distinct function. If you are looking for a hot-dip galvanization, this piece of significant information will be of great support for people like you.

- Pulse fired furnaces with high-speed integration

- Re-circulating hot air dryer

- Waste heat recovery system

- Polypropylene tank for degreasing, pickling, rinsing, and fluxing

- Flux regeneration and filtration plant and flux heating system

- Fume extraction systems for acid and zinc, fume enclosures

- Quench and passivation tanks

- Work jigs, drosser, kettle cover, skimmer, and ash buckets, etc

- Jigging and unjigging stations

- Surface treatment tanks and storage tanks

There are a host of other significant machines and tools integral to the sophisticated plant. The process involves immersion of a metallic road, iron, or steel in the molten lava of zinc. Subsequently, a metallurgical reaction takes place. As a result, external layers of both the metals develop bonds, a homogenous and highly resistant surface. This surface is a protective shield!

What’s Flux Heating System?

If you are on the search for a galvanization plant, don’t forget to seek critical information about the flux heating system. It’s an integral part of the pivotal system. Why should buyers and companies emphasize this sophisticated machine? Even a minute compromise could prove out to be disastrous. Hence quality matters!

The flux heating system is designed to uniformly heat the flux across the tank. Technology and specifications may vary from company to company. Many companies fabricate systems with inbuilt competency to control the temperature automatically that enables efficient fluxing.

According to industry experts, maintain the temperature of the flux solution in the range of 60 to 80 degrees Celsius. Is there any particular reason behind that? Yes. The flux solution in this temperature range causes fewer zinc splashes and less ash formation.

Understanding Flux Filtration System

This system again plays a major role in conducting a flawless galvanization process. Its intelligent usage lowers zinc consumption. Balanced chemical composition in the flux tank is of paramount importance as flux gets polluted with the iron ions that get mixed in the flux while processing the material in the flux tank.

The chemical bonding of iron with a flux solution causes the generation of excess ash and dross. Therefore, it’s significant to control the iron content and pH in the flux to prevent the formation of ash and dross. These measures enable to maintain the efficiency of the galvanizing process and at the same time prevent the expensive zinc from being wasted.

Understanding Flux Recovery System

This is again an integral system related to the galvanization process. An industrial enables the removal of unused flux, left out during the process. This flux is collected and recovered to be used for future processes. Endeavours should be to control the wastage of expensive flux material.

Galvanized products are all around. It wouldn’t be an exaggeration if we say that galvanization has become an integral part of our lives. Directly or indirectly, we come across hundreds of things in our day-to-day life inspired and manufactured through the process of galvanization. Who doesn’t travel by four-wheeler? It’s galvanized? Many of you might have traveled by aircraft. The air machine uses several parts with a galvanized coating. Wind Mills are providing wind energy for various objectives, be it electricity for households or manufacturing companies. Leveraging the galvanization process, wind mills’ durability is further strengthened.

Why does iron metal rust?

Iron has its intrinsic properties, when exposed to inclement weather, reacts with air and salt, and develops rust. In scientific terms, it’s called reduction and oxidation. You might have come across deteriorated iron railings at railway stations, power supply poles in your colony, etc. It’s all because of rust. Another classic example is an iron-made ship. A ship is continuously exposed to saline seawater.

Moving forward, let’s understand the galvanization!

What is the galvanizing process?

According to industry experts, galvanization is a sophisticated process wherein a protective zinc coating is applied on iron or steel and tools fabricated using metal. Hot-dip galvanization is the most sought-after process for conducting galvanizing process. A few companies are providing hot-dip galvanizing plants in Ahmedabad, India.

Over the years, hot-dip plant technology has witnessed numerous innovations. It’s been a blessing in disguise for various industries depending on galvanization, including shipping, road, energy, and construction.

Industry experts have rightly called the galvanizing furnace the heart of a hot-dip galvanizing plant. An ideal furnace is identified with a few salient features, including energy efficiency, durability, and performance.

To further understand the process, it’s pertinent to take a deep dive into the subject. Under the hot-dip galvanization process, a metal-made rod or any tool that requires galvanization is immersed in a bath of molten zinc. It leads to a metallurgical chemical reaction. A multi-layered coating of zinc-iron alloy and zinc metal emerges. It’s because of a diffusion process. As a result, the galvanized coating is perpendicular to our surfaces. Owing to this feature, uniform thickness is created across the metal surface.

Benefits of galvanization process

It’s time to shift gear! What are the advantages of the galvanized steel? Let’s understand the benefits of galvanization:

Galvanization stands for longevity

That’s right! Galvanization amplifies durability to a great extent. This is one of the major reasons why hot-dip galvanizing plants in Ahmedabad are in huge demand not only across India but also overseas. Any idea about the thickness of zinc coating applied on metal during the process of galvanization? You would be shocked to know that the thickness of the coating is – 85 microns. For readers’ benefit, let’s interpret it further with an ordinary example. The thickness of the zinc layer is equivalent to the thickness of an A4 size sheet. This tiny thickness layer has the strength to protect the metal structure for nearly 100 years. Is it? Yes! This clearly reflects the impact created by galvanization. So, next time when you visit a photocopier for a photocopy, just check an A4 size paper!

Affordable

People often cast aspersion over galvanization. It has nothing to do with quality or benefits. They think it’s beyond the reach of ordinary businessmen. It’s too expensive, needs a fat budget to execute. The real picture is –if you consider the durability provided by hot-dip galvanization to the structure, then it has been found, it’s affordable and can benefit industries of various domains.

Practically proven

Our lives revolve around galvanized structures galore, from morning to evening. There are many transport and foot over bridges world over constructed decades ago still existing in brilliant condition. This is a classic example proving the durability of galvanization. Galvanization is reliable! So, next time when someone says a hot-dip galvanizing plant in Ahmedabad can save metal for 100 years, trust him!

It’s scientific

The process of galvanization isn’t a miracle in any way; it’s a proven scientific process that occurs through metallurgical reaction. This clearly demonstrates – it’s reliable! Nothing fabricated or a figment of imagination.

Galvanization is sustainable

Sounds a bit interesting! Yes, if you are inclined towards the environment, you would appreciate galvanization. Galvanization has been found highly sustainable as it produces minimal waste.

There are several hot dip galvanizing plant manufacturer Ahmedabad India, provide the galvanizing plant. With the numerous years of experience in the field, Arvind Corrotech is the leading turnkey hot dip galvanizing plant supplier.

The galvanizing plant is with the aid of using par one of the maximum ecological strategies of galvanizing the metal with the zinc. The process is done to make the meta corrosion-free and make it durable for a long time. The manufacturerus all in one package with the several units and provide the hot dip galvanizing. With the packages in which metal are uncovered to severe atmospheric conditions. The hot dip galvanizing firms make these products to galvanized with the zinc.

- Metal Pipes

- Electrical Poles

- Road Side Barriers

- Steel Towers Used For Electrical Transmission

- Cable Trays

- Steel Towers Used For Mobile Towers

- Fasteners

- Hardware Industrial Items

This plant is a genuine production system throughout some steps of the galvanizing plant. Other pre and post processes should be followed by the plant exporter. A spectrum of the pickling or process tanks used for removing the extra dust, and they consist of the acid or other chemicals.

The tanks are resistant to a wide range of chemicals, also they have great mechanical properties. The tanks are supplied from the exporter Ahmedabad India available in the PPH pp and pp-FRP as well. All the storage tanks should be easy to operate, and the tanks should be manufactured in vinyl ester fitted with the granite.

All the tanks are available in various shapes and sizes that suit every batch of the pickling material. The things such as sheet metal components, wire, pipe mills, and cr mills can be pre-processed before galvanizing plant.

Components To Be Used For Galvanizing Plant:

- Pre-Treatment Tanks

- Pulse Fired High-Velocity Furnace

- Zinc Kettle

- Acid Fume Extraction System

- Flux Heating System

- Acid Storage Tanks

- Effluent Treatment Plant

The zinc galvanizing process can be followed step by step by using the component listed above.

The Hot Dip Galvanizing firms make the galvanizing plants that can help you in galvanizing with the:

- Rapid Application

- Reliability

- Proper Mechanical Resistance

- Lower Production cost

- Easy Maintenance & Testing Of Galvanizing Quality

- Ultimate Protection

At Last,

The material can be galvanized by using the perfect hot dip galvanizing plant if it is employing top quality that credits all the components of the plant. Besides, to check the associated with the galvanizing plant, you should consider the top manufacturer, supplier, or exporter.

The enormous and remarkable economic challenges have introduced the need to utilize limited resources in an efficient and effective manner. The impact of currency devaluation along with globalization and environmental concerts are changing the overall governance to a high extent.

Why Make Generous Usage of Hot Dip Galvanizing Plant?

High technological advances have enabled some exclusive ways of deploying services in a cost-effective and timely manner. The generous usage of hot dip galvanizing plant is a great example. Yes, along with having a firm grip on preventing corrosion; it has proved to be an environmental friendly and cost effective solution.

Galvanizing plants have made it easy for governments to take best decisions for building and expanding their infrastructures to remain competitive in:

- Tourism

- Transportation

- Economy

Turnkey Hot Dip Galvanizing Plant Helping to Prevent Corrosion

Governments continue to focus on expanding militaries and managing political systems to expand national infrastructures. To ensure that these facilities operate at optimal level, effort is being geared to preserve them from corrosion,turnkey hot dip galvanizing plant has proved to be of great help.

Such plants will prevent controlling corrosions to a high extent, thus ensuring maximal services to citizens. Top hot dip galvanizing firms are adopting the most suitable technological solution to the hazards will truly extent the usefulness of such facilities. Also, it will benefit both the nation.

Painting and Plating Remains No More Effective Today

Generally, painting and plating are common methods used to prevent the ill effects of corrosion. Though partly effective, it will be a good idea to go with a top manufacturer of galvanizing plant. It has proved to be a reliable, cheap and durable method of preventing rusting hence causing less harm to the environment.

In case you are unable to halt to the best decision, better have a detailed discussion with a reliable supplier in Ahmedabad. It will give you an insight to the merits along with methods of maintaining these plants.

Remarkable Benefits of Hot Dip Galvanizing Plants

Want to know what attracts industries towards hot dip galvanizing plants? Below are some remarkable benefits assured by top exporters in India:

- Low cost and less labour intensive

- Highly durable with less maintenance

- High life expectancy of minimum forty years

- Process is simple, controllable and straightforward

With a wide variety of options available in the market, it will become easy to select the most suitable galvanizing plant for your needs.